Advantages

- Specially designed rotor effectively avoid reducing size of contaminants.

- Discharge contaminants as per different specific gravity.

- Remove contaminants as early as possible to reduce the burden of pulper and other downstream equipment.

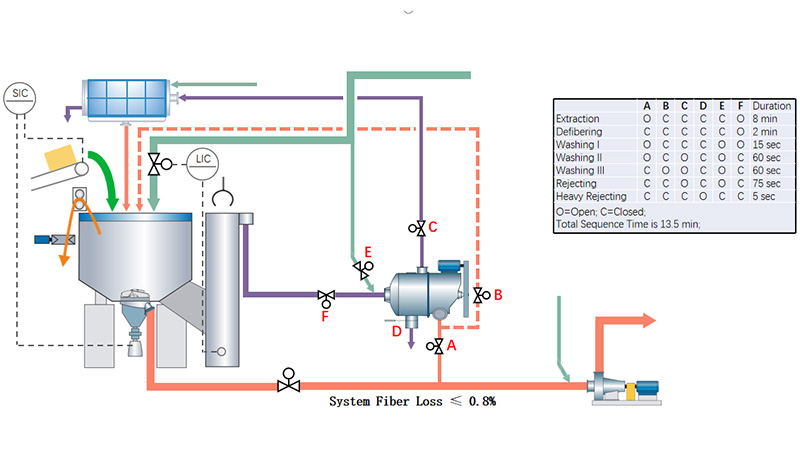

- Automatic control system makes reject discharging easier and reliable.

- Front cover can be opened, maintenance and repair more convenient and fast.

Stucture

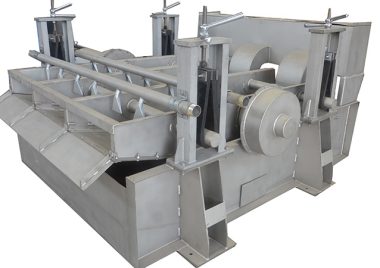

The equipment is mainly made of protegulum , machine case, rotor device, base, driving device, etc .

Protegulum install inlet pipe and heavy impurity discharge pipe. Ahead of Machine case has light impurity discharge pipe, end part have flange connecting with outlet disc of rotor device, on the two sides have connecting backplane connect with base. Rotor device mainly consist of rotor, main shaft, outlet disc, screen plate device, bearing base, driving support, large belt, etc.

Rotor material is wear-resisting cast steel material, rotor device have adjustable bolt to adjust clearance between screen plate and rotor. Base is used for supporting machine case and driving parts. Driving device mainly consist of motor, small belt, motor support and vee belt. The structure of machine refers to attachment drawing.

Technical Data

| Model | ZSF1 | ZSF2 | ZSF3A |

| Nominal Volume (m3) | 1.2 | 3 | 5 |

| Consistency(%) | 3-5 | ||

| Capacity(T/D) | 15-45 | 40-120 | 60-150 |

| Motor Power(KW) | 45 | 75 | 160 |