Vibrating Screen for paper pulp

The vibrating screen is used for paper pulp and fiber recovery treatment in the papermaking industry. It can be used for both low consistency and high consistency pulp and is suitable for the coarse screening stage to remove large impurities from the pulp.

Advantages

- Applicable for all kinds of reject handing at the last stage of screening and seperating.

- Adopting double-row self-aligning roller bearing, reliable and stable operation.

- Perfect screening ability with self-washing, high screening efficiency, easy operation and maintenance.

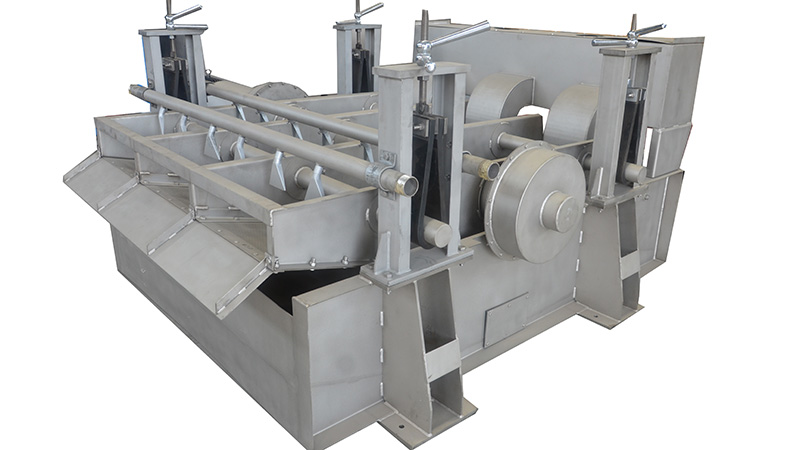

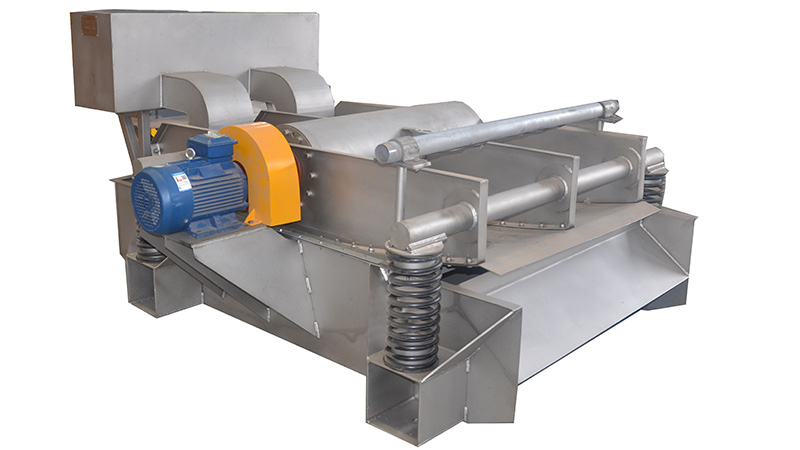

Structure

The machine consists of screen body, vibration exciter, damper spring, stock storage box, water spray pipe, elastic coupler, etc.

Screen body consists of screen frame, screen plate, gas seal chamber, the whole screen body supported on four elastic damper springs. vibration exciter consists of eccentric block and bearing installed on main axis, fix on screen frame’s centre-of-gravity position by bolt, motor connect with elastic coupler to let main axis roll, eccentric block let screen body vibrate, inside of stock storage chamber, equip a flashboard which can adjust stock level, by adjusting stock level, let stock immerse at bottom of gas seal chamber to form gas sealing.

Technical Data

| Model | ZSK1 | ZSK2 | ZSK3 | ZSK4 | |

| Screening Area (㎡) | 1 | 2 | 3 | 4 | |

| Consistency (%) | Hole:(%) | 1—1.5 | |||

| Slot:(%) | 0.5—0.8 | ||||

| Capacity (T/D) | Hole (T/D) | 7.5—25 | 15—50 | 22.5—75 | 30—100 |

| Slot (T/D) | 3.5—7.5 | 7—15 | 10.5—22.5 | 14—30 | |

| Motor Power (Kw) | 2.2 | 3 | 4 | 5.5 | |

We are a factory and manufacturer. When purchasing vibrating screens, make sure to choose the source manufacturer. We will provide you with the best quality service and the most competitive prices.