Structure

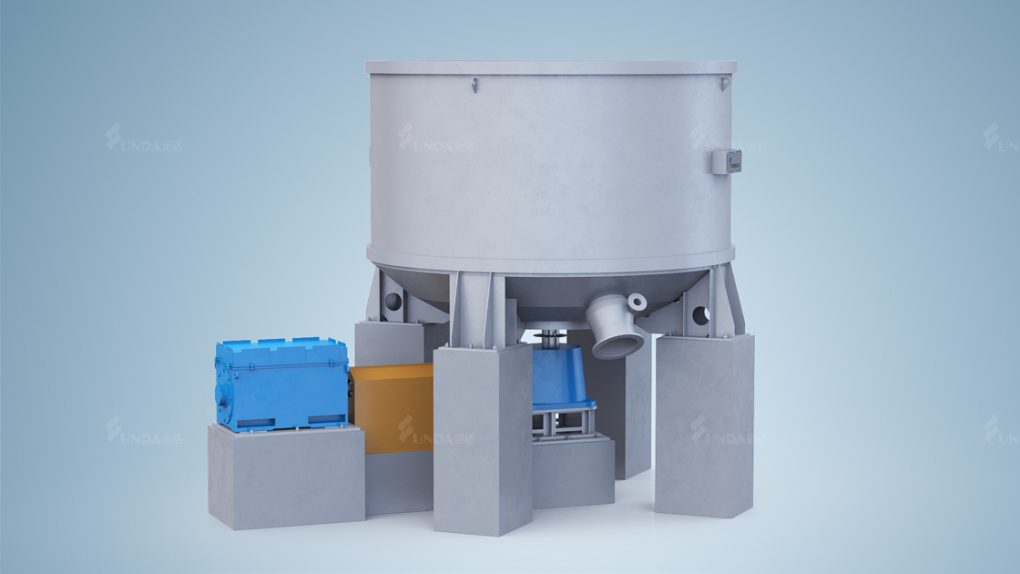

High Consistency Pulper is a vertical structure, which is mainly composed of vat body, rotor, transmission part, screen plate,rack.

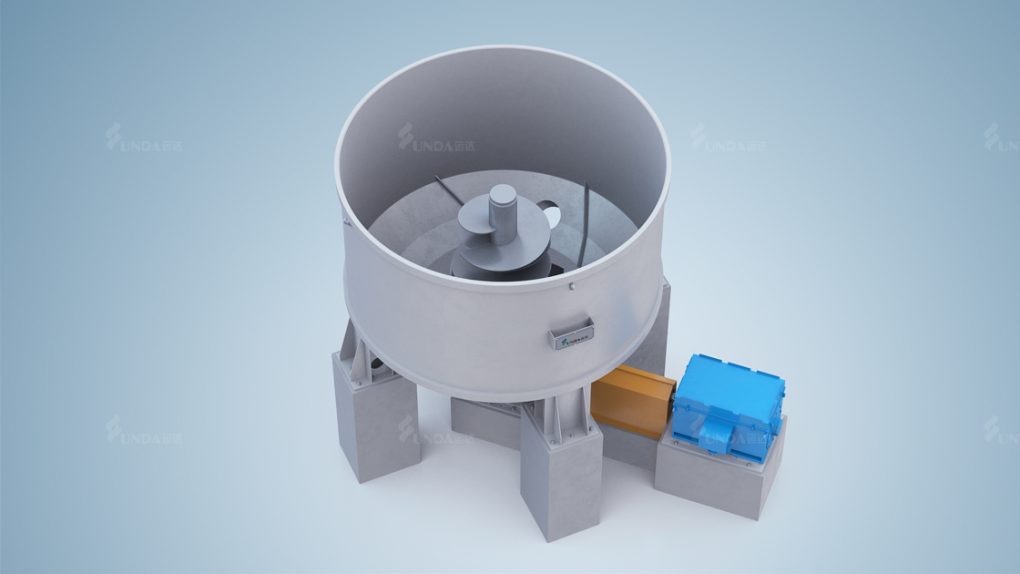

The rotor device is composed of a rotor and a bearing supporting device with screw flights around the rotor.

The bearing supporting device adopts a wear resistant structure of which all of them are non-contact sealings except the stuffing box to reduce unnecessary energy consumption.

The vat body is welded by steel plates, and the upper part is equipped with angle steel flanges for expanding the volume when discharge with low consistency during high consistency operation.

The lower part is equipped with a flange at the bottom of the vat connected with the screen plate,there are three baffle plates at the bottom of vat to form recirculation when stock backflow, and orifice plate is used as dilution water channel when deflaking under high consistency, the bottom of vat is equipped with the stock outlet and the stock was discharged after pulping is completed.

The lower part of the vat is equipped with a transmission part, which is composed of a main shaft, bearings, bearing base and belt pulleys.

A large aperture screen plate can be installed below the rotor according to the technology requirements. It can also be used as a low consistency pulper by replacing the rotor and screen plate.

The bracket is consisted of four tubular column and reinforcing rebar for supporting vat body, The upper part of reinforcing rebar is welded with the vat body, and the lower part is welded with the baseplate to make the supporting more fastness.

Advantages

- Tower-shape spiral rotor has a strong defibering ability meanwhile not broken the impurities.

- Suitable for high consistency stock of 12-18%,energy saving and chemicals saving.

- Compact construction,easy operation and maintenance.

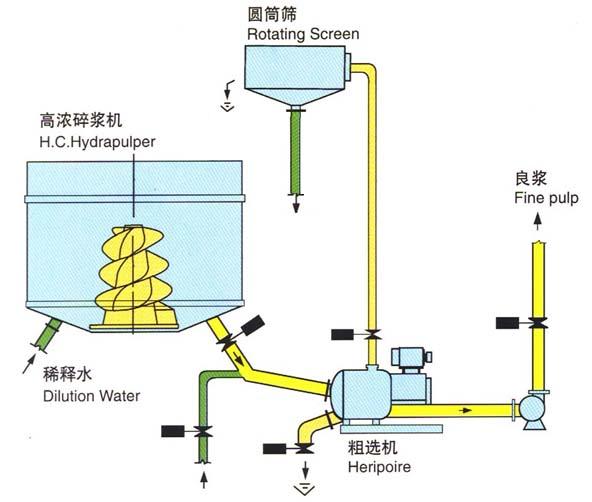

Principle

Under the Condition of the high consistency of 12%-18%, 60~90 ℃ temperature ,waste paper will be deflaking quickly through the action of chemicals at the same time.

The stock motions is from up to down along the surface of spiral rotor and finally throws to cell wall from the bottom of rotor, then stock moves upward along the cell wall,which is taken to bottom by rotor forming strong hydraulic impacting and shearing action, The stock generate friction and rubbing to form single fiber finally. under the action of fiber friction and deinking agent, the ink was peeled off from fiber surface.

So as to realize high consistency pulping and deinking effect; Fibers such as Tetra Pack are separated from the aluminum plastic.

The Pulping process

Technical Parameter

| Model | ZDSH3 | ZDSH4 | ZDSH6 | ZDSH9 |

| Nominal Volume (m3) | 5 | 10 | 15 | 30 |

| Consistency (%) | 12-18 | |||

| Capacity (T/D) | 20-30 | 30-50 | 60-70 | 140-180 |

| Motor Power (kW) | 110 | 185 | 315 | 560 |

Project