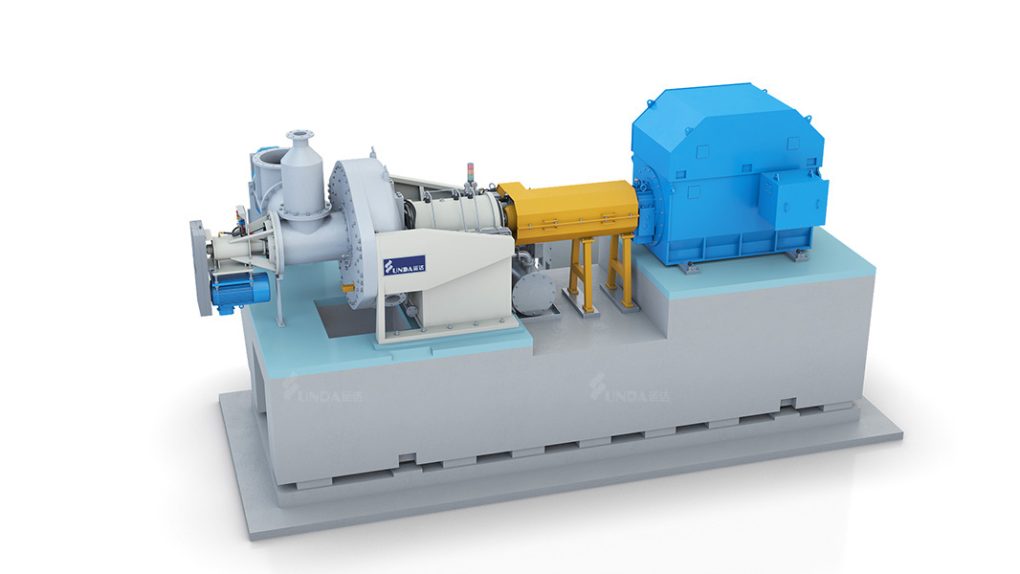

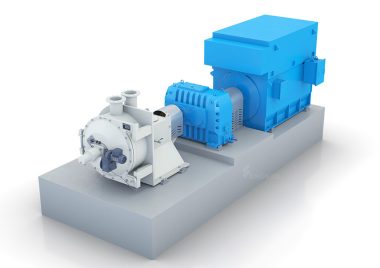

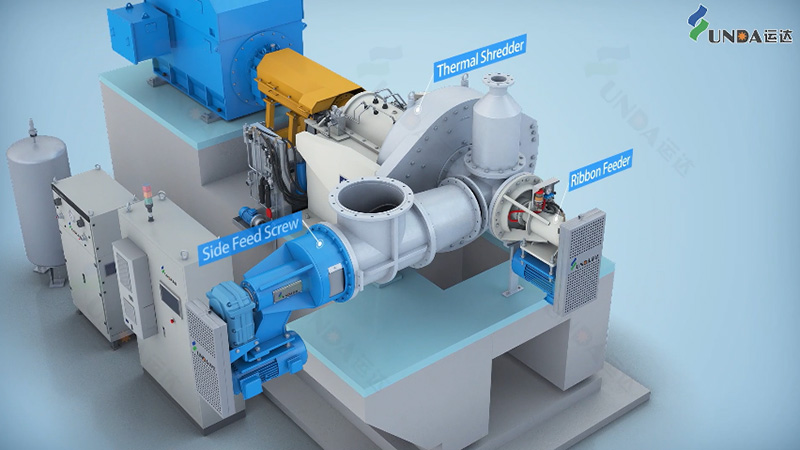

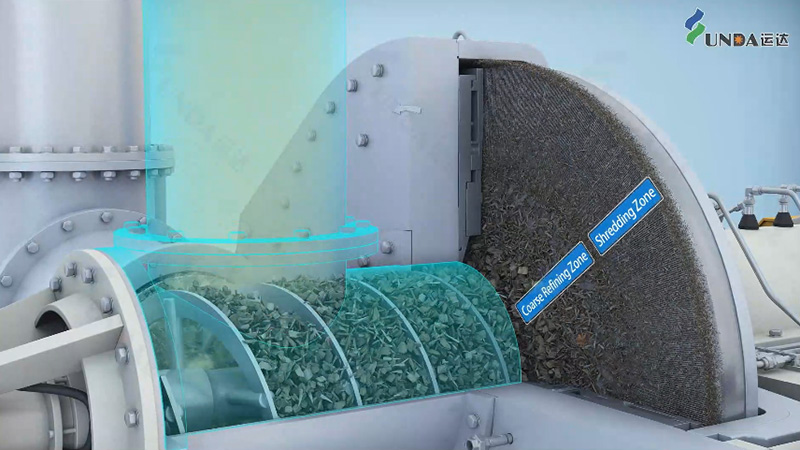

High Consistency Refiner(Thermal Shredder), Yunda Innovation design of the thermal shredder have a number of patents,which has superior performance, safety and reliability and wide range of raw materials. The main structure is composed of three parts: Thermal Shredder, Ribbon Feeder and Side feed Screw.

Raw materials such as wood chips, bamboo chips are going into the Host Pulping Zone through the high-speed rotating ribbon feeder, and after pulping chips enter the fiber coarse refining zone and fiber hair-like shreds zone. And it shredded into uniform hair-like shreds under the action of the rotary and stationary discs, where the chemicals are added at the same time. Compared to the chips, the hair-like shreds has a larger specific surface and higher chemical reaction efficiency, which reduce chemical consumption and pollution.

Advantage

- Compared to traditional high consistency refiners, Yunda Innovative Thermal Shredder has multi- advantage:

- The clearance between refiner plates is accurately adjusted through electronic and hydraulic control, which is up to 0.01mm;

- The Thermal Shredder is equipped with shock sensors and vibration sensors to ensure safe and stable operation of the equipment;

- Dynamic balancing comes with G2.5 level accuracy, which ensure smooth operation and lower noise;

- Adopting a patented rubber damping limit device to ensure stability of operation process;

- Replacing the refiner plates does not require dismounting the pipeline, and it equipped with a refiner plates holder and specialized tooling, which shortens the time for replacing the refiner plates, reduces downtime and improves start-up efficiency.

Yunda Thermal Shredder is energy-saving, high efficiency, stable and reliable, comparable to international first-class brands; It is a key equipment for i-CTMP.

Technical Data

| Model | GPM244 | GPM250 | GPM256 | GPM262 | GPM268 |

| Configuring Refiner Size/mm | 1120 | 1270 | 1420 | 1575 | 1728 |

| Refiner Size/inch | 44″ | 50″ | 56″ | 62″ | 68″ |

| Density/% | 25-35 | 25-35 | 25-35 | 25-35 | 25-35 |

| Capacity/(T/D) | 90-140 | 120-180 | 170-260 | 240-340 | 300-450 |

| Improve karsting after grinding/°SR | 10-15 | 10-15 | 10-15 | 10-15 | 10-15 |

| Design pressure of grinding chamber/Bar | 8Bar | 8Bar | 8Bar | 8Bar | 8Bar |

| Spindle rotation speed(50Hz/60Hz)/rmp | 1500/1800 | 1500/1800 | 1500/1800 | 1500/1800 | 1500/1800 |

| power/KW | 1800kw-3550kw | 2500kw-4500kw | 4000kw-7100kw | 5600kw-9000kw | 10000kw-15000kw |

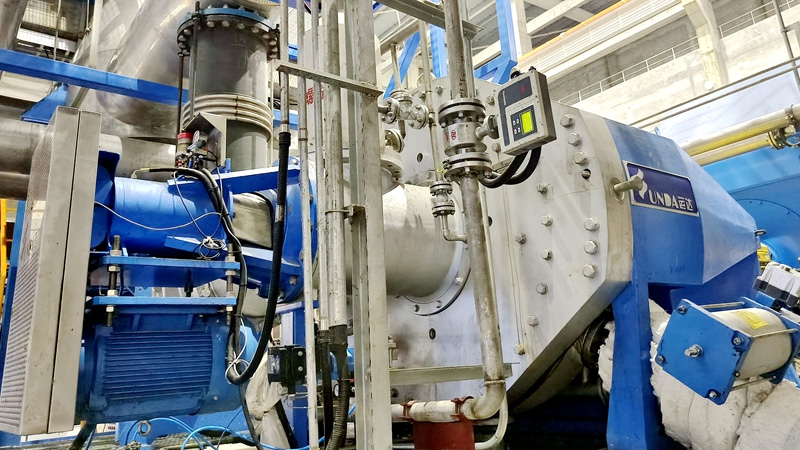

Case