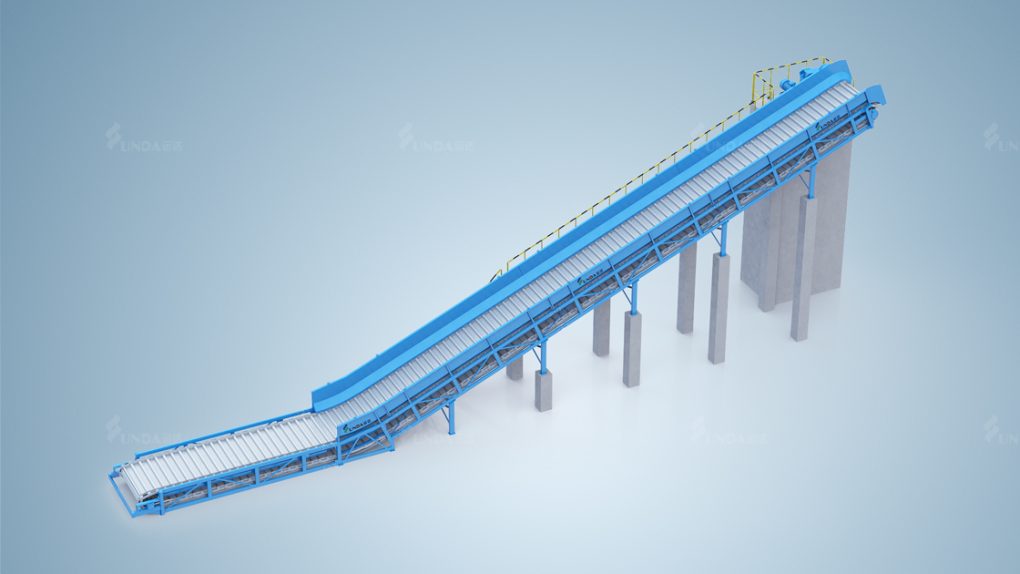

Working Principle

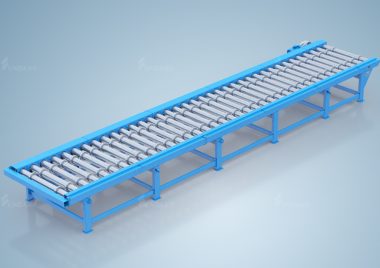

Composed of driving device, tail wheel device, tension device, chain plates and machine frame.

- Driving Device

This device has motor, reducer, transmission device and driving chain wheel, etc. The driving force is transmitted to the main shaft from the driving device by a pair of bush roller chain wheels, and then slot plates are driven. The drive chain pulley drives two chip drag chains and slot plates to run along the track by adopting two six-tooth chain wheels.

- Tail Wheel Device

This part helps change the running direction of chain plates. It consists of tail wheel shaft, two tail wheels and bearing, etc.

- Tension Device

Spiral tension method is adopted to adjust the tightness of the drag chain.

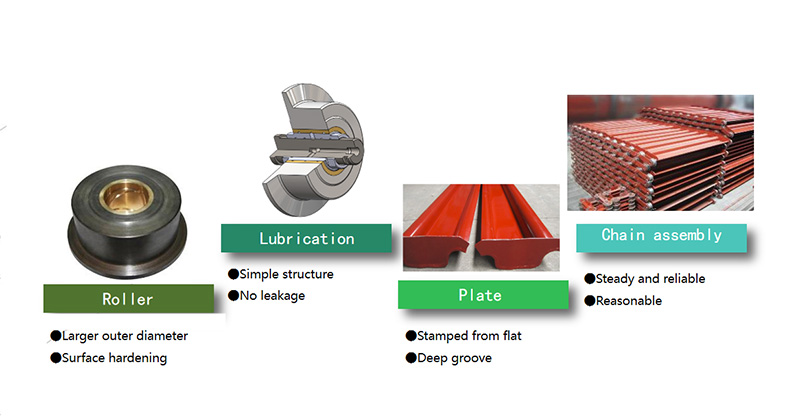

- Chain Plates

Made up of drag chain and slot plates. It uses impact-resistance, stable and reliable chip drag chain. Rollers set inside the inner chain plates runs along the track to reduce the friction drag and abrasion. Slot plates are fastened by bolts and drag chain.

- Machine Frame

Including head frame, tail stand and intermediate frame, made by welded channel steel, angle steel and reinforced plate. There are four light rails for rollers running.

Project

Technical Parameters

| Model | BWF1200 | BWF1400 | BWF1600 | BWF1800 | BWF2000 | BWF2200 | BWF2400 |

| Effective Width (mm) | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 |

| Capacity (m³/h) | 65-210 | 80-225 | 95-300 | 110-345 | 140-390 | 180-430 | 240-500 |

| Speed (m/min) | 1.2-10 | ||||||

| Incline | Bale and pulp board ≤22° bulk waste paper ≤45° wood board ≤45° | ||||||

| Raw Material | Bales, pulp board, bulk waste paper, wood chips | ||||||

| Raw Material Max Size (mm) | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 |

No.1 Market Share in China 500+ References

| Nine Dragon | Yinge Group |

| Sun Paper | PT.PABRIK Paper |

| Andritz | NBM |

| Daoqin Paper | Zhengtai Holding |

| Century Sunshine | Huafeng Paper |

| Lee&Man Paper | Jianhui Paper |

| Krishna Paper | Muda Paper Mills Sdn |

| Century Sunshine | Baoshi Paper |

| Huatai Group | Tiger Forest & Paper |

| PT.Pelita Paper | Kanghua Paper |

| PT.Grace Paper | Kemei Paper |

| etc. |

Case