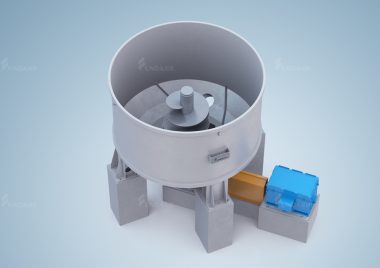

Yunda ZDSZ Series middle consistency hydrapulper is a kind of vertical pulp equipment, which is used for pulping various pulp boards, broke and waste paper, the pulping consistency is up to 5%-8%, as well as high defibering ability.

Structure

ZDSZ series Medium Consistency Pulper is composed of vat body, rotor and transmission device,etc.

The vat body is welded by stainless steel, the top of vat has a conical opening to avoid stock from splashing.

The lower steel flange connects with transmission part. there are guiding plates installed at the bottom of vat to form recirculation when stock backflow, reject channel and reject outlet are cocated in the bottom.

Below the vat is transmission device, which is main shaft, bearing, bearing base, belt pulley and so on.

Below the rotor is screen plate, it can select holes of different sizes according to customer needs.

Principle

When the vat of pulper is filled with 1/2 water, and then start-up motor, the pulp board, broke or waste paper are evenly put into the vat. The defibered and separated stock will flow out through screen hole.

The heavy contaminant will be collected in settling tank and regularly discharged. Due to the special structure of the rotor of this series of hydraulic pulper, when the rotor rotates, the stock is thrown from the center to the surroundings, and a vortex is generated in its center, so that the pulp board and broke are shredded in a wet state.

The paper sheets and fiber bundles that have not been shredded are further defibering in the gap between rotor and screen plate.

And because of the special shape of the end of the pulping blade, the screen hole will not be blocked.

Advantages

- By adopting new S-type middle consistency rotor, combined with intelligent pulping control system, compared with conventional pulper, the energy consumption of pulping is reduced by 30%.

- High defibering ability and wide application range

- Simple structure, easy operation and maintenance

Technical Parameter

| Model | ZDSZ24 | ZDSZ25 | ZDSZ26 | ZDSZ27 | ZDSZ28 | ZDSZ29 |

| Nominal Volume (m3) | 10 | 15 | 20 | 25 | 30 | 40 |

| Consistency (%) | 5-8 | |||||

| Capacity (T/D) | 40-60 | 60-90 | 90-130 | 120-170 | 150-200 | 220-290 |

| Motor Power (kW) | 90 | 132 | 185 | 250 | 250 | 315 |

Project

- Project Name: Yusen Paper

- Add: Hebei & Liaoning, China

- Annual Capacity:40,000 Tons & 60,000 Tons

- Paper Product Grade: Tissue

- Raw Material: Wood

- Add: Hebei & Liaoning, China

- Supply Scope: Roll Conveyor, MC Pulper, HC Cleaner, Double Disc Refiner, , Agitator, Vibrating Screen, Machine Screen, and so on.