Advantages

- Conical shell is in favor of separating and removing light and heavy impurities and defibering at the same time.

- Separate light and heavy impurities effectively, defibering sufficiently, energy-saving.

- Able to adopt automatic rejecting as required, reliable operation.

Working Principle

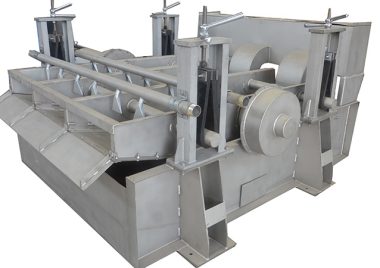

ZDF fiber sorter is new equipment developed for making fine stock from wastepaper. It helps separate heavy and light impurities in wastepaper stock and further defiber with higher efficiency but lower energy cost, thus different from traditional process which contrarily demands higher energy cost with lower production efficiency. The machine especially works well on separating impurities (like paper fastener, sand, plastic film, plastic paraffin, wax asphalt) in waste paper to let stock clean and improves product grade.

Technical Parameter

| Model | ZDF2C | ZDF3C | ZDF4C | ZDF5C |

| Vane Diameter | Φ560 | Φ720 | Φ980 | Φ1100 |

| Inlet Pressure (MPa) | ≤0.3 11 | |||

| Consistency (%) | 2.0-3.0 | |||

| Capacity (T/D) | 30-50 | 60-80 | 100-180 | 160-260 |

| Motor Power (kW) | 37 | 55 | 90 | 132 |

Working site