i-OCC(Drum Pulping System)

OCC system & paper production line

Yunda supply a complete OCC line for paper mill, professional and thoughtful one-stop service for you.

Yunda i-OCC stock preparation system has the advantages of high yield, high quality, high reliability and low energy consumption. The system realize the idea of less intermediate stock chests, which can save appx. 20% of the floor spaces; using of the eco-jet mixing technology provides lower investment, lower energy consumption and lower maintenance cost; group start / stop provides easy operations

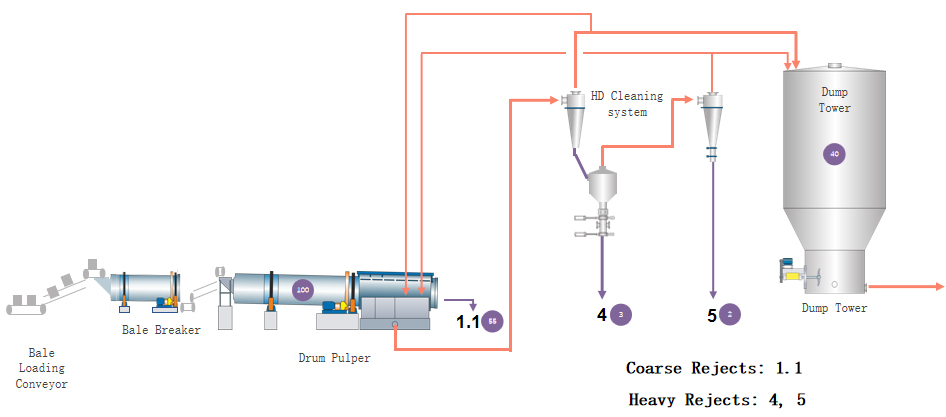

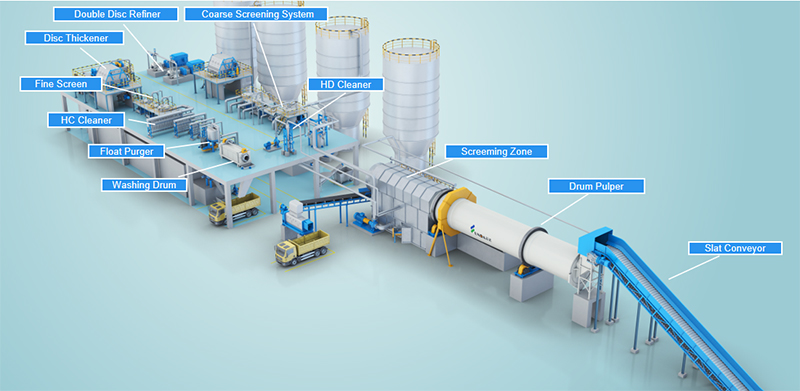

Drum pulping system

The waste paper after bale breaking goes evenly into the Drum Pulper with less hits, accelerated water absorption and increased pulping efficiency. with fully disintegration by rubbing, The stock will be diluted to a lower consistency of 3 - 5% by the spraying water coming out of the shower pipe in the screening section. The accepted stock goes through the screen holes. And the impurities such as waste plastics are discharged from the reject end. The stock in the bottom vat of the Drum Pulper is pumped into the Two Stages HD Cleaner,the accept from the 1st stage goes into the Dump Tower and the Reject is collected in the Settling Tank and will be pumped from the top to the second stage for further cleaning. Accept of the 2nd stage is led back to the Pulper and the heavy contaminants is dumped to the sand separator to collect the sands from water.

The stock after the Dump Tower is pumped into the Coarse Screening System, Reject of the first stage goes to the 2nd stage via one eco-jet mixer directly, And reject of the 2nd stage goes further though a Float Purger and a Reject separator, finally the light impurities collected for further treatment. Accept goes to the fractionation system and after that short fiber goes after thickening to the storage tower.

Long fiber enters the LC Cleaner plant in 4 stages design; light particles was removed by centrifugal forces; In the fine screening stage Oda screen basket provides high stickies removal efficiency, high throughput, and energy-saving; The final stage of the fine screen has additional under the rotor dilution which helps to either reduce excessive thickening of the reject inside the screen basket or clean the impurities completely, accepts from different stages are all going forward and combined together and fed into the Long Fiber Disc Thickener.

The long fiber mat is knocked off by the knock-off shower and then enters the Disperser through Screw Press, Plug Screw, Shredding Screw, Heating Screw for further treatment. after that the stock is conveyed to the long fiber storage tower and will be further refined by the Double Disc Refiner, Yunda PM Double Disc Refiner is reliable, energy-saving and high quality of beating.

i-OCC is not only good in stock preparation but also good in reject handling, which it provides human-machine harmony, green and environment friendly, and is the priority for OCC treatment.

The case of gray cardboard production line

For Details of the Project of the OCC line please Contact Yunda!

i-OCC Recycled Fiber Technology

OCC/mixed waste paper main components :

- Fiber and Debris ,Ash.

- Rejects( Plastics,Wires & Strings,Metals,Non-Ferrous Metals,Sand, Stone & Glass,Stickies...)

In OCC Stock Preparation:

- To Retain as much Fiber as possible (High Yield);

- Typical System Losses: Fiber ≤2.8%, Debris ≤6.5%;

- To Retain certain amount of Ash;

- To Remove as much Rejects as possible;

- Typical Stickies Removal Efficiency: ≥90%;

Proper Reject Sorting and Treatment is not only a way of being Environmental Friendly but also Brings good Margins…