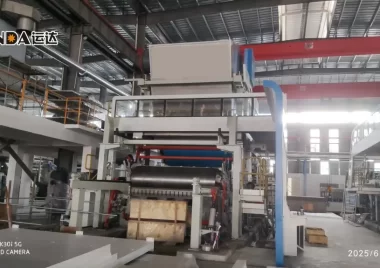

Kraft Paper Making Line

What Is Kraft Paper?

Kraft paper machines are categorized into kraft paper machines, corrugated paper machines, paperboard machines, etc. according to the type of paper produced.

Kraft liner board machine use waste paper,white shavings ,virgin pulp as material to make high quality Kraft paper board. Finished products can be made paper roll.

Waste pulp Kraft paper making line

Waste pulp Kraft paper making line link: https://www.yundapm.com/solutions/i-occ/

Virgin pulp Kraft paper making line

Virgin pulp making process (CTMP process) link: https://www.yundapm.com/solutions/i-ctmp/

Pulp Turned Into Paper

- 1. Forming dehydration

Dispersing the pulp evenly is an important part of turning the pulp into paper that meets the requirements of use, this needs to dilute the pulp to a consistency of 0.3%~1% to make the fibers more evenly dispersed, and then sprays the pulp evenly onto the forming wire through the headbox, and dehydrate through the gravity and vacuum of the wire part reach 20 % dryness.

- 2. Press dehydration

Paper sheets with a dryness of about 20% need to be squeezed by press rollers to further remove moisture. Generally, they will go through 2~3 times of pressing to reach a dryness of about 50%.

- 3.Forming dehydration

After the initial pressing and dehydration, in order to allow the water to evaporate quickly, it needs to be dried by high-temperature steam, and the high-temperature steam is sent into the steel roller (drying cylinder), and the surface temperature of the drying cylinder is transferred to the wet paper sheet, so that the paper sheet Moisture drops below 10%.

- 4. Rolling

The last step in the utilization of waste paper is to roll the paper into a roll with a roller using friction force, and then produce different types of paper according to different needs.

- 5. Finished product

The processing plant will purchase base paper for processing according to the end use, These papers will be processed into cartons, packaging bags, packaging boxes, etc. used in daily life through different processing methods such as printing, coating, laminating, bronzing, die-cutting, and box-gluing.

What machine is used for making Kraft paper?

We can design the production line according to the raw materials type, Production capacity, pulp products and mill-specific requirements. If you are looking for this machine, do not hesitate to contact us or leave your requirements here.

-

Jiangxi Lulin’s 200,000-ton packaging paper projectGet details

Jiangxi Lulin’s 200,000-ton packaging paper projectGet detailsThe complete stock preparation system and approach flow system supplied by Zhengzhou Yunda for the PM7 line of Jiangxi Lulin’s 200,000-ton packaging paper project has been successfully put into operation. Developed with Yunda’s strong R&D capabilities, the system was engineered to optimize both production efficiency and energy consumption from the start. Moving forward, Zhengzhou Yunda…

-

Guangxi Qingyun Tissue Paper projectGet details

Guangxi Qingyun Tissue Paper projectGet detailsZhengzhou Yunda provided a complete set of pulping and approach flow systems for Guangxi Qingyun Paper Industry’s 150,000-ton annual production project of tissue paper, which has successfully been put into operation. The system adopts a modular design concept and intelligent control solutions, providing a solid guarantee for the project’s efficient and stable operation. On May 27,…

-

Gansu Yusen Tissue PaperGet details

Gansu Yusen Tissue PaperGet detailsOur customer Yusen Group was Founded in 2006, Yusen Group is an integrated enterprise engaged in the research and development, production, and sales of tissue paper and sanitary products. It has been awarded “Craftsmanship Product of the Chinese Tissue Paper Industry” for three consecutive years and ranks among the top ten in the industry. The…

-

Five Continents Special Paper 450,000 tons packaging paper ProjectGet details

Five Continents Special Paper 450,000 tons packaging paper ProjectGet detailssuper-screen

-

The i-CTMP High Yield Pulping Production line of Shan YingGet details

The i-CTMP High Yield Pulping Production line of Shan YingGet detailsShan Ying Paper Industry (Guangdong) Co., Ltd. Yunda successfully launched the high consistency system (including steaming equipment, softening equipment, and pressure high consistency refining equipment) and low consistency system (including low consistency screening equipment and low consistency refining equipment) for Shan Ying Paper Industry (Guangdong) Co., Ltd.’s 320 TPD bamboo fiber project. This project uses…

-

Shandong Tianhe i-BCTMP pulping line upgrade projectGet details

Shandong Tianhe i-BCTMP pulping line upgrade projectGet detailsIn October 2024, Yunda’s key equipment for the upgrade project of the existing chemical thermal mechanical pulping (CTMP) line at Shandong Tianhe Paper Co., Ltd. has entered the installation and commissioning phase. The supply scope includes key equipment such as plug screw, balanced bin, T-tube with blow back valve, discharge screw, refining system, and screening…

-

Guangxi Sun Cultural PaperGet details

Guangxi Sun Cultural PaperGet detailsProject Introduction: On November 30, 2021, Guangxi Sun Paper Industry Co., Ltd. successfully put into operation its 3.5 million tons integrated wood-pulp-paper project, including a 550,000-ton cultural paper project. Yunda supplied the pulp bales conveyor equipment for this project, which has been operating stably. In June and November 2020, Yunda and Guangxi Sun Paper…

-

Qianan Boda Cultural PaperGet details

Qianan Boda Cultural PaperGet detailsProject Introduction: In March 2021, Yunda and Qian’an Boda established a cooperative relationship, with Qian’an Boda placing a one-time order for 12 PM26 double disc refiners from Yunda. In July 2021, the refiners were gradually delivered to the project site. In 2022, the Qian’an Boda double disc refiner project successfully commenced operations.

-

Vietnam Thuận An Paper PM8 ProjectGet details

Vietnam Thuận An Paper PM8 ProjectGet detailsCustomer Background: As a leading player in the Vietnam’s paper pulp industry, Vietnam Thuận An Paper Industry has been dedicated to the production and sales of Testliner and Fluting paper since its establishment in 1990. With over 30 years of steady development, it has built a complete industry chain from waste paper recycling to product sales. The annual…

-

EG-Paper PackagingGet details

EG-Paper PackagingGet detailsEG-Paper is one of the largest paper mills in Egypt, which mainly produces various corrugated paper and test liner paper. Since its opening in 2008, The production capacity and the business scope have been continuously expanded. At present, the production capacity has reached 200,000 tons. In addition to Egypt, its business also expanded to Italy, Saudi Arabia, Lebanon, Jordan,…

-

400t/d Bamboo Fiber i-CTMP ProjectGet details

400t/d Bamboo Fiber i-CTMP ProjectGet detailsNew generation of Chemical Thermal Mechanical Pulping (CTMP) process technology. Yunda’s i-CTMP pulping system is an new generation of Chemical Thermal Mechanical Pulping (CTMP) process technology. Compared with the traditional CTMP process, i-CTMP has many advantages, such as lower investment cost, better flexibility with variations in raw materials, good pulp quality and low production cost.…

-

Guangxi Kebao ZDG425 Drum PulperGet details

Guangxi Kebao ZDG425 Drum PulperGet detailsProject In May 2022, Guangxi Kebao Paper Industry Co,.ltd. signed a contract of pulping system with Yunda including ZDG425 drum pulper, bale breaker, chain conveyor. The ZDG425 drum pulper has a diameter of 4250mm and a total length of 38 meters. Daily production capacity up to 1300 tons. In June 2023, under the careful installation…

-

The Rebuild of IKPP OCC LineGet details

The Rebuild of IKPP OCC LineGet detailsThe Rebuild of OCC Coarse Screening in Indonesian App Group IKPP Mill was successfully accepted The customer spoke highly of the commissioning results From June 19 to June 22,2023, the Rebuild Project supplied by Yunda for the production base of APP in Indonesia have been continuously operation for 3*24 hours , The performance of the equipment…

-

Heng’an Group Paper Tissue Paper lineGet details

Heng’an Group Paper Tissue Paper lineGet detailsCustomer Founded in 1985, Hengan Group is currently the largest manufacturer of tissue paper and maternal and child hygiene products in China. It was listed on the Hong Kong Stock Exchange on December 8, 1998. On June 7, 2011, Hengan International was included in the Hong Kong Hang Seng Index constituents. Hengan owns four well-known…

-

250,000 tons cardboard paper,Vietnam THUẬN ANGet details

250,000 tons cardboard paper,Vietnam THUẬN ANGet detailsproject On April 22, 2022, Yunda and VietnamTHUẬN AN Paper Industry Shun reached a cooperation agreement to provide the entire pulping line for their PM8 250,000 tons of carton board paper project. The scope of supply includes chain conveyor, medium concentration pulper, grading screen, screen front screen, double disk pulper and other equipment. This cooperation…