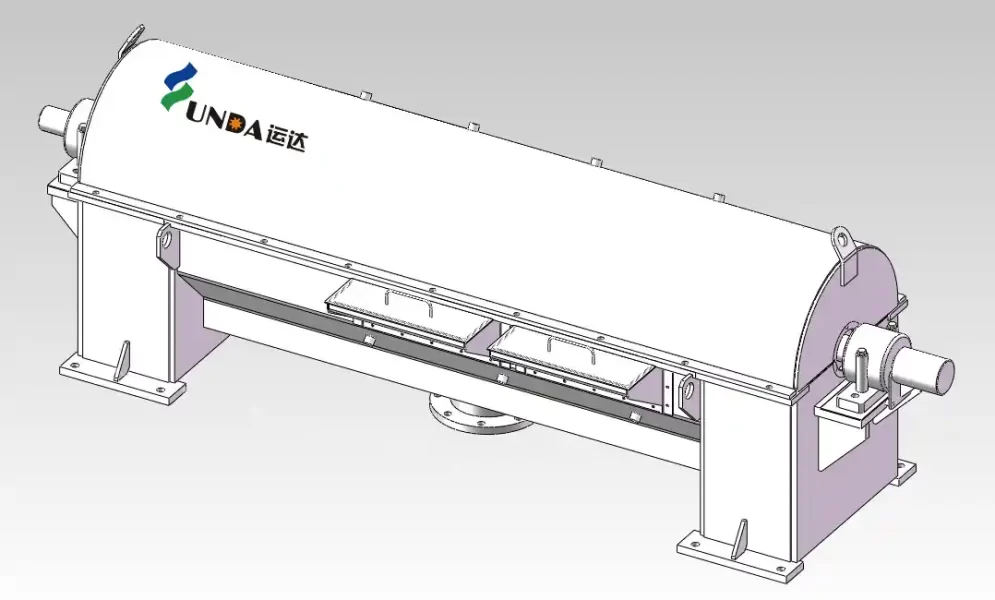

The reject separator is mainly used for pulp deflaking and impurity separation.

In the pulp and paper production process, pulp slurry often contains a large amount of impurities, such as sand, gravel, metal fragments, plastics, ropes, and incompletely defibered fiber bundles. If these impurities are not removed in a timely manner, they will not only affect pulp quality but may also cause equipment wear or even lead to shutdowns. Therefore, reject separators have become one of the indispensable and critical pieces of equipment in pulp and paper systems.

I. Main Functions of Reject Separators in the Pulp and Paper Industry

1. Defibering the Pulp and Improving Fiber Dispersion

While separating contaminants, the reject separator gently defibers the pulp, effectively breaking up fiber bundles and distributing fibers more uniformly. This creates favorable conditions for subsequent screening and cleaning processes.

2. Efficient Separation of Heavy and Light Impurities

Through mechanical action and fluid dynamics principles, the reject separator effectively removes heavy impurities such as sand, metal, and glass, as well as certain light contaminants like plastics and stickies, significantly improving pulp cleanliness.

3. Recovery of Usable Fibers and Reduction of Raw Material Loss

A properly designed reject separator minimizes fiber loss with the rejects, thereby increasing fiber recovery efficiency and reducing the overall cost of recycled pulp or virgin pulp production.

4. Protection of Downstream Equipment and Stable Operation

By pre-treating the pulp before it enters pressure screens, fine screens, or cleaners, the reject separator reduces the load on downstream equipment and lowers the risk of plugging, wear, and unplanned shutdowns.

II. Working Principle of Reject Separators for Pulp and Paper Applications

Reject separators commonly used in the pulp and paper industry typically adopt a combined structure of screw defibering and separation. The operating process mainly includes the following steps:

First, pulp containing impurities enters the equipment through the inlet. Driven by the rotating screw rotor, the pulp is continuously agitated and conveyed forward, gradually breaking down fiber bundles and achieving preliminary defibering.

Next, under the combined effects of centrifugal force, gravity, and screening structures, fibers and contaminants begin to separate. Qualified fiber pulp passes through the screen openings or exits through the accept outlet to the next process, while higher-density impurities concentrate at the bottom or reject end of the equipment.

Finally, the separated impurities are continuously discharged by the screw conveying mechanism, enabling non-stop reject removal. The entire process is stable and continuous, making it well suited for the long-term operation requirements of pulp and paper production lines.

III. Advantages and Key Features of Reject Separators

1. Integrated Defibering and Separation Design

Reject separators integrate pulp defibering and impurity separation into a single unit, effectively simplifying the stock preparation process and reducing equipment quantity and system complexity.

2. Low Fiber Loss and High Recovery Rate

By adopting a gentle defibering method, the equipment ensures effective separation while minimizing fiber breakage and loss. This makes it especially suitable for recycled pulp and high-contaminant pulp applications.

3. Continuous Operation for High-Capacity Production

The equipment supports continuous pulp feeding and continuous reject discharge, offering stable operation and meeting the high-consistency and high-throughput demands of modern pulp and paper production lines.

4. Adaptability to Various Pulp Types

Whether processing recycled pulp, chemical pulp, or mechanical pulp, reject separators maintain reliable separation performance and show strong adaptability to raw materials with high ash and impurity content.

5. Easy Maintenance and Long Service Life

With a relatively simple structure and key components made of wear-resistant and corrosion-resistant materials, reject separators require minimal maintenance, operate at low cost, and offer a long service life.

IV. Typical Application Scenarios

In the pulp and paper industry, reject separators are widely used in:

Coarse screening systems for recycled pulp

High-consistency cleaning systems

Impurity pre-treatment before hot dispersion

Treatment of screen tailings and reject pulp

Technical Data

| Pressure | Maximum Operating Pressure: 69 kPa |

| Flow Rate | Maximum Capacity: 30 ADMT/day (Air-Dried Metric Tons per day) |

| Consistency | Feed consistency typically below 2.5%. |

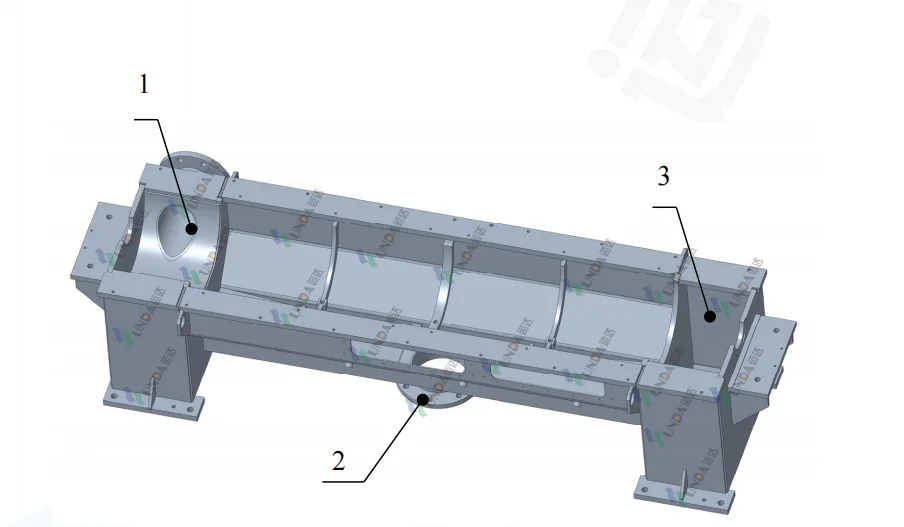

Main Components

1.Base

The pulp enters through inlet pipe No. 1, the accepted pulp is discharged from outlet No. 2, and the reject pulp is discharged from reject box No. 3.

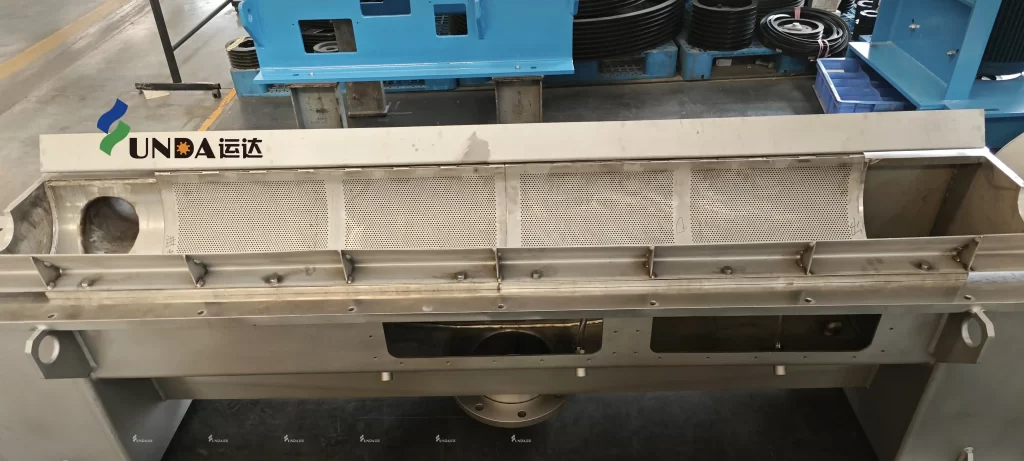

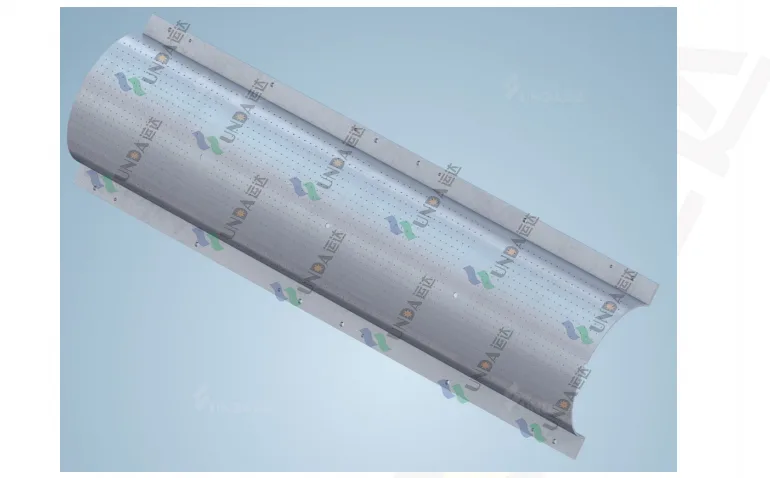

2.Screen Plate

The screen plate is fixed above the base. As the rotor rotates, the accepts are filtered through the screen plate and discharged from the outlet pipe located beneath the base.

3.Rotor

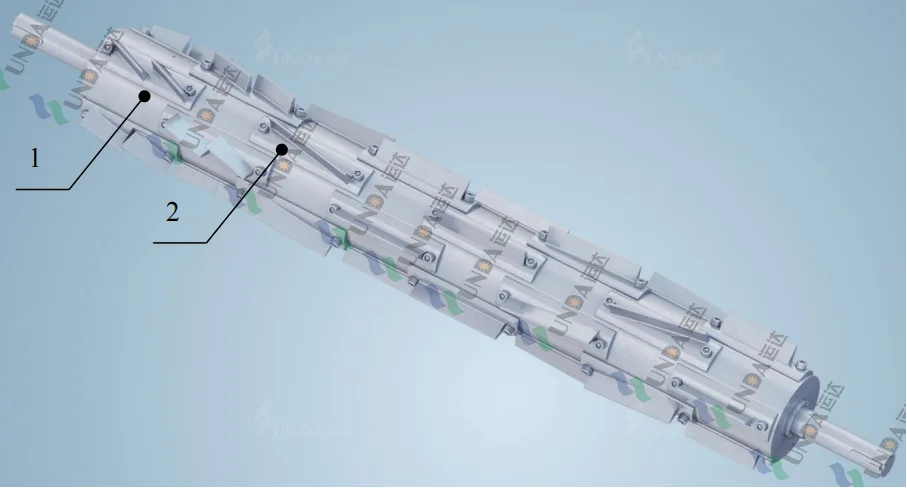

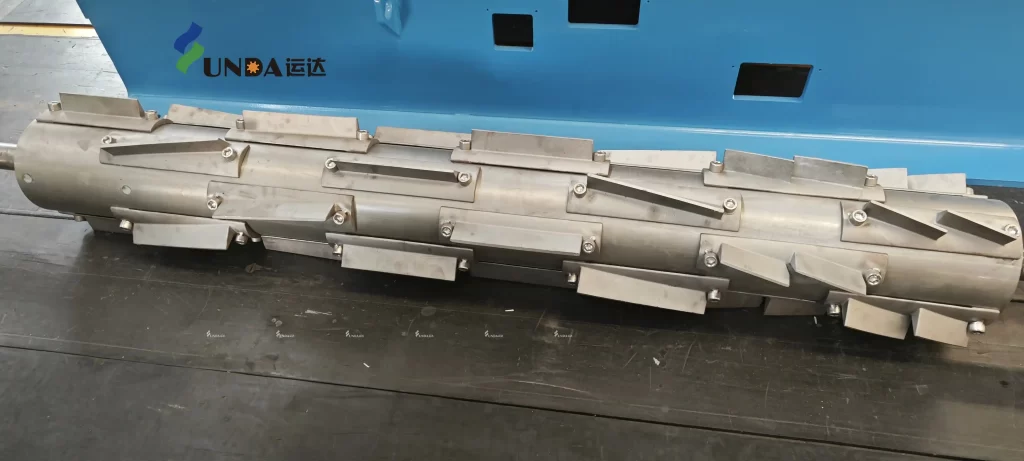

The rotor assembly consists of: main Shaft (No. 1) and blades (No. 2)

As the pulp and paper industry continues to raise its requirements for product quality and operational stability, the role of reject separators in pulp defibering and impurity removal has become increasingly important. Proper selection and application of reject separators not only help improve pulp quality but also reduce operating costs, providing strong support for paper mills to achieve efficient, stable, and sustainable production.

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project