Advantages

- Ragger and Rope Cutter are used together with pulper, to drag the rope out of pulper and cut off for easy transportation.

- Long moving route of cutter to avoid rope block and plug.

- Designed with double hydraulic cylinders to ensure enough cutting force.

Ragger is used for coarse screening and cleaning and match with hydrapulper, make contaminants in waste paper such as wires, strings, plastics, yarns and alike twine continuously during the running of hydrapulper, forming a rope and pulled out and discharged. Thus the furnish is preliminarily cleaned. The machine has advantage of higher work efficiency, lower energy consumption, simple structure and easy to operate and maintain, etc.

Grapples are used in continuous pulping system with lifting equipment to take heavy and light contaminants out from the sediment well. Grapple is mainly made of en air cylinder, four tines and a connecting rod. Grapple and sediment well work together to form a cleaning system. When grapple goes down, tines are opened to the biggest size. When drop above pulp level in sediment well it can takes out light impurities, while under pulp level it can takes out heavy impurities. The rated loading of grapple reaches 300kg.

Rope cutter is a coarse screening and cleaning equipment, working together with hydrapulper and ragger. The rope fromed by winding contaminatns like wires, strings and plastics, etc. by ragger will be dragged out by ragger, and then cut by rope cutter to desired length and finally carried way.

Structure and Principle

Ragger:

Ragger is made up of rack, motor, reducer, pressing wheel, landing gear, reel and guide wheel, etc. The motor drives the reel via reducer. The reel runs slowly and pulls out ropy impurities. The running speed and direction of twined rope is adjustable accordingly. The twined rope is compacted by compressing wheel and the pressure is also adjustable by landing gear. Guide wheel supports the twin rope and reduce its running resistance. The ragger structure is simple and compact.

Grapple:

Grapples are made of four tines, air cylinder, connecting rod, lifting ring base, pin roll, cylinder set casing, hinge and so on. Auxiliary attachment: pneumatic triad, two-position four-way magenetic exchange valve, air supply and so on. Cleaned air and atomized oil in the triad enter the cylinder then the piston rod drives the tines by articulated mechanism. Close the tines to grab and open to load.

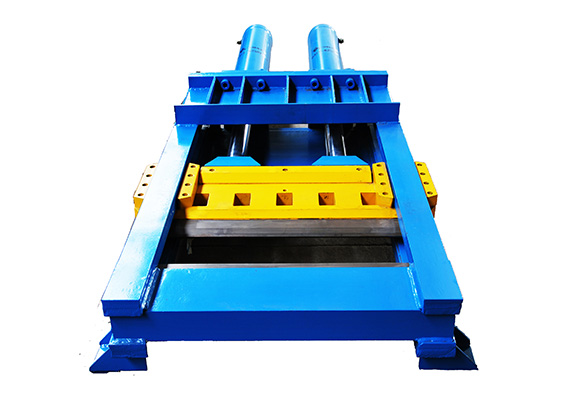

Cutter:

Components: rope cutter comprises frame, blade, hydraulic cylinder, hydraulic pump station and control parts. The frame is mainly used to fix hydraulic cylinder, blade and blade table, and as the directive slide track for blade. Blade and blade table are the main parts to cut off rope. Raw material of blade and table is alloy tool steel with high hardness, toughness and abrasive resistance. The function of hydraulic pump station supplies power (hydraulic energy) of rope cutter. Control part is used to control the operation of rope cutter.

Technical Data of Ragger

| Model | JSJ600 |

| Roping Speed (m/h) | 0-60 |

| Motor Power (KW) | 4 |

| Outline Dimension (L*W*H) (mm) | 1900*1700*1700 |

Technical Data of Rope Cutter

| Model | QS35 |

| Working Pressure (MPa) | 25 |

| Hydraulic Pressure (T) | 2*50 |

| Cutter Route (mm) | 850 |

| Pump Station Motor Power (KW) | 11 |

| Oil Tank Volume (L) | 180 |

| Equipment Weight (Kg) | 1650 |

Technical Data of Grapple

| Model | ZD1 (4 TINES) | ZD2 (2 TINES) | ZD3 (4 TINES) | |

| Rated Load Lifting Capacity (Kg) | 1000 | 1500 | 2000 | |

| Load Capacity (Kg) | 300 | 800 | 1300 | |

| Bucket Capacity (m3) | 0.05 | 0.4 | 0.2 | |

| Outline Dimension (mm) | When Closed | Φ700*1410H | 940*1050*1910 | Φ1120*1950H |

| When Opened | Φ1050*1350H | 1580*1050*1940 | Φ1560*2114H | |

| Rated Air Pressure (MPa) | 0.6 | 0.6 | 0.6 | |

| Air Cylinder Tension (Kg) | 1800 | 1800 | 2200 | |

| Working Temperature (℃) | -15-50 | -15-50 | -15-50 | |