Detrasher VS Reject Sorter For processing heavy reject and fiber recovery

The Detrasher and Reject Sorter are specialized machines designed for separating heavy rejects and recovering valuable fibers.

Features of Detrasher VS Reject Sorter

Detrasher

- Located in Pulping Stage

- Feed Consistency: 3-4%

- Repulping function with rotor

- Minimum fiber loss;

- Heavy reject load permitted;

- No separate pump is needed;

- Used in conjunction with the trash well and the drum screen, keep pulp clean;

- Less maintenance requirement

Reject Sorter

- Located in Coarse Screen Stage

- Feed Consistency: 0.8-1.5%

- Deflaking flakes to prevent loss of usable fiber;

- Processed tail reject is virtually moisture-free, which helps reduce the reject treatment costs.

- Simple operation;

- No pressure;

- No fiber in the reject;

- Fit for various capacity;

- Less maintenance requirement

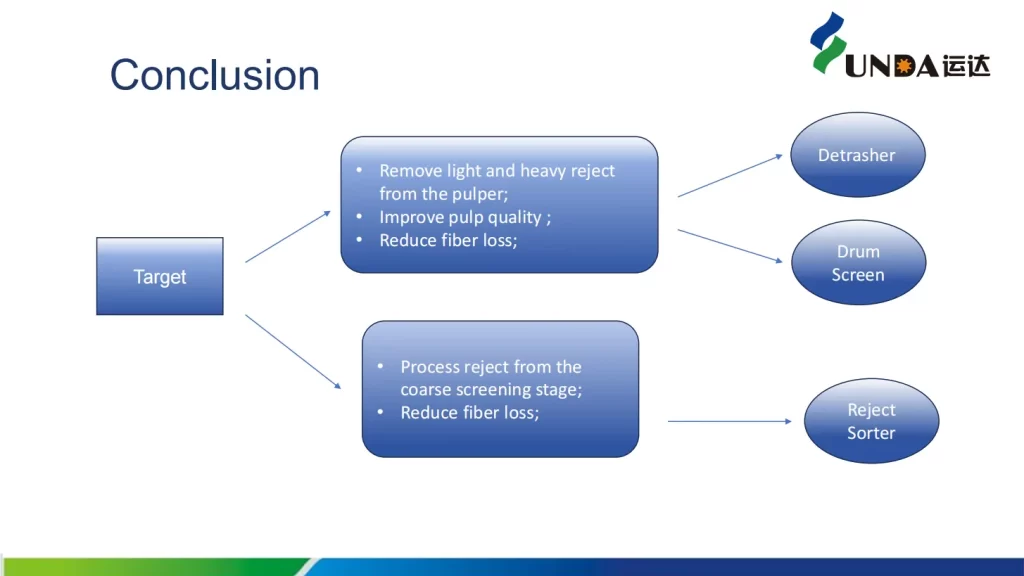

Conclusion

If your target is

- Remove light and heavy reject from the pulper;

- Improve pulp quality ;

- Reduce fiber loss;

You can choose Detrasher or Drum Screen .

If your target is

- Process reject from the coarse screening stage;

- Reduce fiber loss;

You can choose Reject Sorter .

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project