What is vibrating screen

The vibrating screen is a screening device where the screen plate generates vibration. The vibration disrupts the fiber layer formed on the screen plate, allowing the fibers to continuously pass through the screen holes. The screening process involves the continuous formation of fibers on the screen plate, which are then disrupted by the vibrating force.

Vibrating screen purpose

The vibrating screen for paper pulp industry is primarily used in the coarse screening stage of pulp screening. After the pulp cooking process, it removes large impurities such as knots, shreds, wood chips, as well as sand particles, stone debris, and other coarse materials carried by the raw materials, in order to protect the equipment in the subsequent processes.

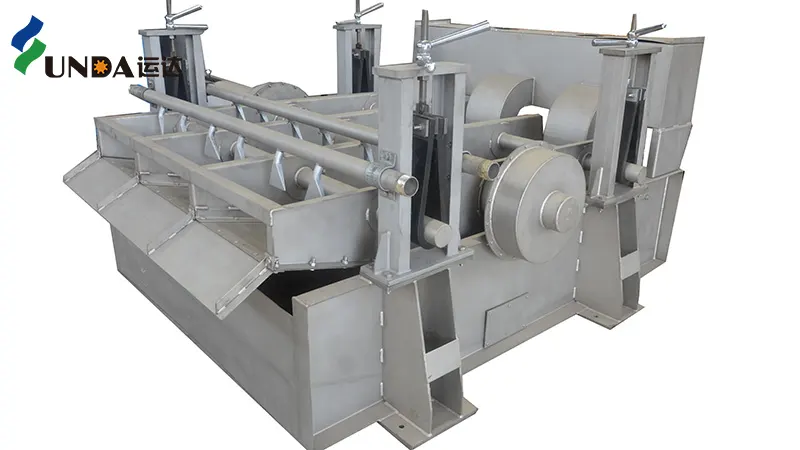

ZSK series self-cleaning vibrating screen

The ZSK series self-cleaning vibrating screen is designed reasonably with strong screening capacity and self-cleaning function. It offers high working efficiency, energy savings, low noise, and easy maintenance. It is one of the more advanced screening devices in the pulp and paper industry, primarily used for screening coarse pulp in the pulp and paper industry.

The ZSK series vibrating frame flat screen has advantages such as high knot removal efficiency, low power consumption, and a small footprint, making it one of the ideal coarse screening devices for pulp.

Vibrating Screen Working principle

When stock enter screen body, by self gravity, gravitational acceleration effect of screen body upward vibrate and Instantaneous negative pressure produce in gas seal chamber, let good stock quickly through screen hole/slot and enter stock storage chamber, reject separated on screen plate. When a part of stock through screen hole/slot, a part of stock form a stock membrane on screen plate because of dewatering, hamper continuous screening, when screen body vibrate downwards, stock on screen plate can produce Instantaneous lose weight effect, because screen body drop ,gas in gas seal chamber compacted and produce pressure, through screen plate rush upwards ,rush the stock membrane on screen plate separately, generate self-cleaning effect, ensure screen hole fluent to let stock screen process continuous. Screen body vibrate front and back, let impurities move towards outlet and reject. Water spraying pipe dilute concentrated impurities, be good for continuous screen and wash portable fiber, reduce fiber lose.

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project