Efficiency range

The separation processes and their efficiencies depend on suspension properties such as consistency and flake and debris content. The same processing stages may be used several times in a stock preparation line, depending on the type and quantity of contaminants, to provide better effectiveness and increased reliability of processing machinery

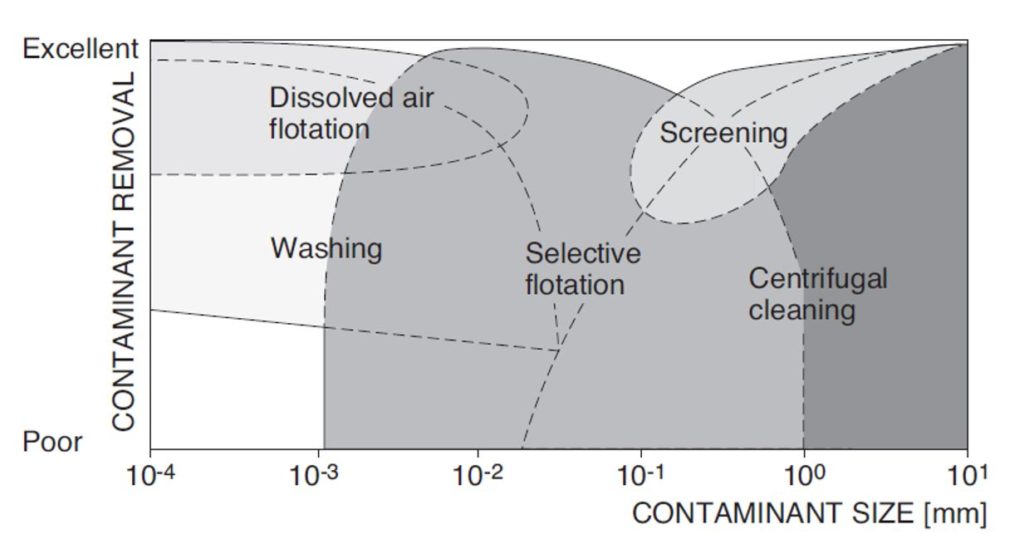

Figure 1 shows the efficiency scatter of various separation processes vs. debris particle size. The separation efficiency of cleaners is excellent at large particle sizes if their density differs sufficiently from that of water and wetted fibres. Otherwise, the separation effect can decrease almost to zero.

Large cubic particles are very well separated during screening, whereas small, flat or deformable particles are hardly separated at all in this process step. Flotation removes only hydrophobic particles but with great efficiency and over a wide size range. Hydrophilic particles remain in the suspension. Washing removes small particles. The efficiency depends on the amount of extracted water. Dissolved air flotation (DAF) or microflotation separates small particles very efficiently.

Main operating parameters of separation processes

lmportant criteria for evaluating the efficiency and cost-effectiveness of each processing stage are the specific energy consumption and stock consistency range. As shown in Table 1, these may vary widely. This may be due to the widely differing technology available. The primary reason is that the energy consumption depends strongly on how much work has occurred in the previous stages for deflaking and contaminant removal and on the requirements placed on the pulp slurry in the downstream process stages. The figures do not include the energy consumption for pumping the pulp slurry from one process step to another.

Table 1. Specific energy consumption and operating consistency of unit processes in recycled-fibre processing., incl. pumps directly connected with the processes

| Unit process | Specific energy demand (kWh/t) | Operating consistency (%) |

|---|---|---|

| Slushing pulper | LC:10-20 / HC: 25-40 | 3-20 |

| Drum pulper (screening) | 20-30/40 | 15-25/(3.5-6) |

| Deflaking | 20-60 | 3-6 |

| Coarse Screening | 15-25 | 3.0 -5.0 |

| Fractionation / Fine Screening | 20-30 | 2.0-3.5 /1.0-2.0 |

| Washing | 5-12 | 0.7-3.0 → 5-8 |

| Dissolved air flotation (DAF) | 10-20 | <0.3 → 0.01 |

| Flotation (selective) | 15 – 35 | 1-1.6 |

| LC-Centrifugal cleaning | 7-16 | 0.8-2.0 |

| Thickening– drum thickener– disc filter | 1-30.3-1.0 | 0.5-3 → 4-60.5-1.5 → 10-12 |

| Dewatering -Screw press | 7-10 | 4-12 → 25-30(35) |

| Dispersing | 30-120 | 25-32 |

| Refining LC (per SR unit) | 3-25 | 3-5.5 |

| Refining HC (per SR unit) | 10-60 | approx. 30 |

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project