Working Principle:

The pulp enters the low consistency cleaner tangentially at a certain pressure, with a pulp consistency of approximately 0.4–1.2%. Inside the conical body, the pulp rotates at high speed from top to bottom, forming a strong vortex.

Heavier impurities are thrown toward the outer wall of the cone by centrifugal force, then settle downward due to gravity and are discharged through the reject outlet at the bottom.

Lighter, clean accept pulp is driven toward the upper part of the vortex. With the assistance of upward backflushing water at the bottom and dilution water, the clean pulp is collected and discharged from the top outlet and conveyed to the accept pulp pipeline.

The backflushing water at the bottom also helps separate fibers carried in the rejects, further reducing fiber loss.

Main Features and Advantages:

- Efficient removal of fine impurities in pulp: Effectively removes sand, grit, dust, ink, fine debris, hot-melt adhesive, foam, plastic particles, and coarse fiber bundles.

- Reduced fiber loss: The bottom backflushing water design effectively minimizes fiber loss.

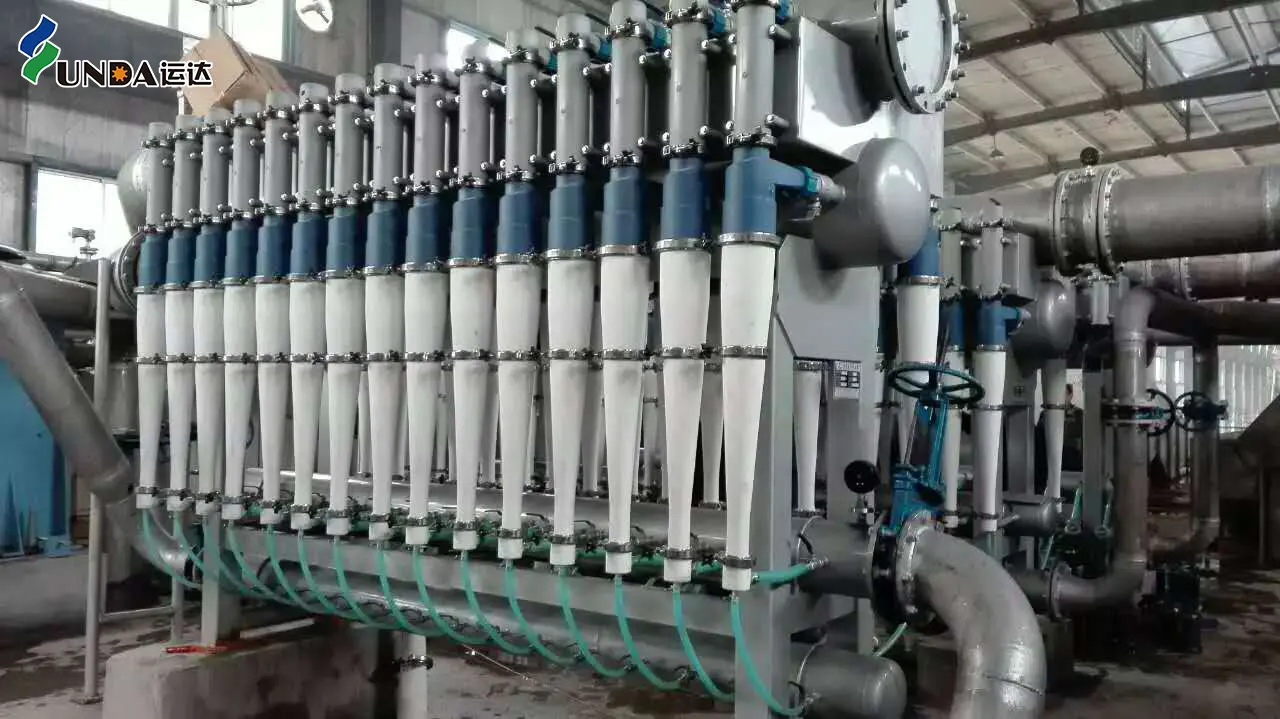

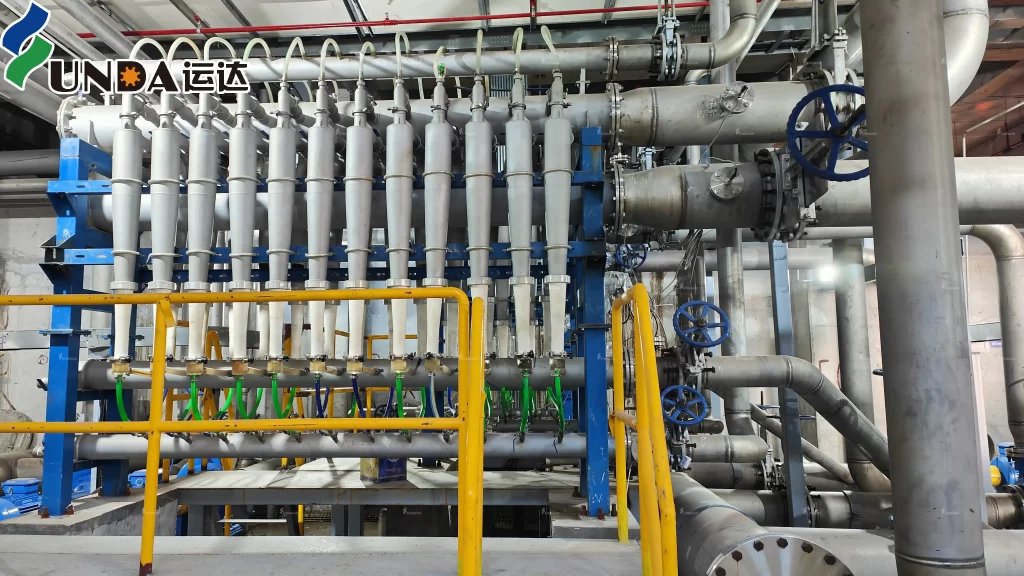

- High wear resistance and long service life: The bottom cone is equipped with a ceramic-lined inner surface, offering excellent wear resistance and extended service life.

- High separation efficiency: An elongated cone design and optimized pulp flow structure significantly enhance cleaning performance.

By adopting a multi-stage cleaning configuration, the system can be flexibly designed according to different production line sections, maximizing impurity removal efficiency while minimizing fiber loss.

Main Technical Parameters:

| Type | sc400 | sc450 | sc600 | sc1000 |

| Position | Last Stage LC Cleaning | LC Cleaning | Last Stage LC Cleaning | Last Stage LC Cleaning |

| Capacity | 400lpm/pc | 450lpm/pc | 600lpm/pc | 1000lpm/pc |

| Inlet Consistency | ˂ 1.2% | ˂ 2.0% | ˂ 1.2% | ˂ 1.5% |

| Inlet Pressure | 0.2-0.3MPa | 0.25-0.35MPa | 0.2-0.3MPa | 0.2-0.3MPa |

| Pressure Drop | 0.13-0.15MPa | |||

| Rejects Discharge Type | Closed, continuous | |||

Scope of Supply and Descriptions:

low consistency cleaner Upper Body With feed and accept pipes, made of stainless steel 304;

low consistency cleaner Upper Cone Housing made of stainless steel 304, inside made of ceramic;

low consistency cleaner Lower Cone Made of ceramic;

Frame Made of carbon steel, with surface paint;

FB Device Connection Method: The connection between the clearner and the rejects adopts a reinforced transparent plastic hose, equipped with a stainless steel ball valve.

FC Device Connection Method: The flushing water pipe is inserted into the center of the glass rejects collection box. The connection between the cleaner and the dilution water pipe adopts a reinforced transparent plastic hose, equipped with a stainless steel ball valve.

Manifolds and Branch Pipes Manifolds for outlet, inlet, accept, reject and flushing water pipe made of stainless steel 304; DN50 shut-off valve of flushing water is for rejects discharge manifolds; Manifolds for flushing water is equipped with check valve; Branch pipe for outlet, inlet, reject and flushing, with stainless steel ball valves only fitted to the inlet and outlet branch pipes;

Shut-off Valves Ball valves for single cleaner inlet/outlet and reject discharge pipe; Ball valves and check valves for back flush water pipe;

Pressure Gauges Diaphragm pressure gauges are installed on the inlet and outlet manifolds.