The medium-consistency pressure screen is a key screening device in the pulping and papermaking process, mainly used for pulp purification at medium consistency. It effectively removes impurities and protects downstream equipment, while reducing energy consumption and fiber loss. It is widely applied in chemical pulp, mechanical pulp, and recycled pulp production lines.

Yunda’s ZNS Series Midium Consistency Pressure Screen is used for coarse screening, fractionating screening and fine screening in the pulping process. They provide excellent screening efficiencies at significantly lower pulse rates.

Features:

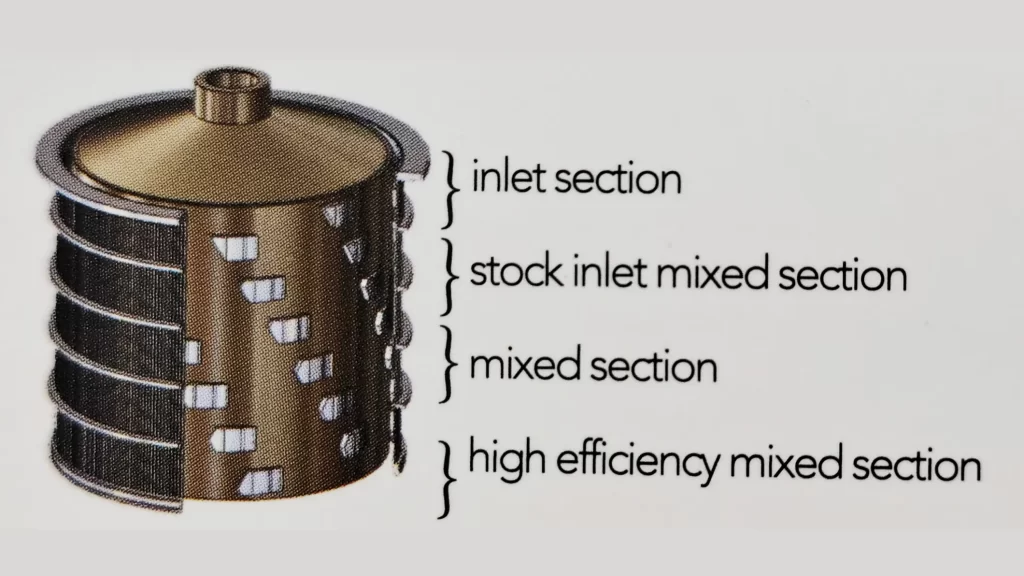

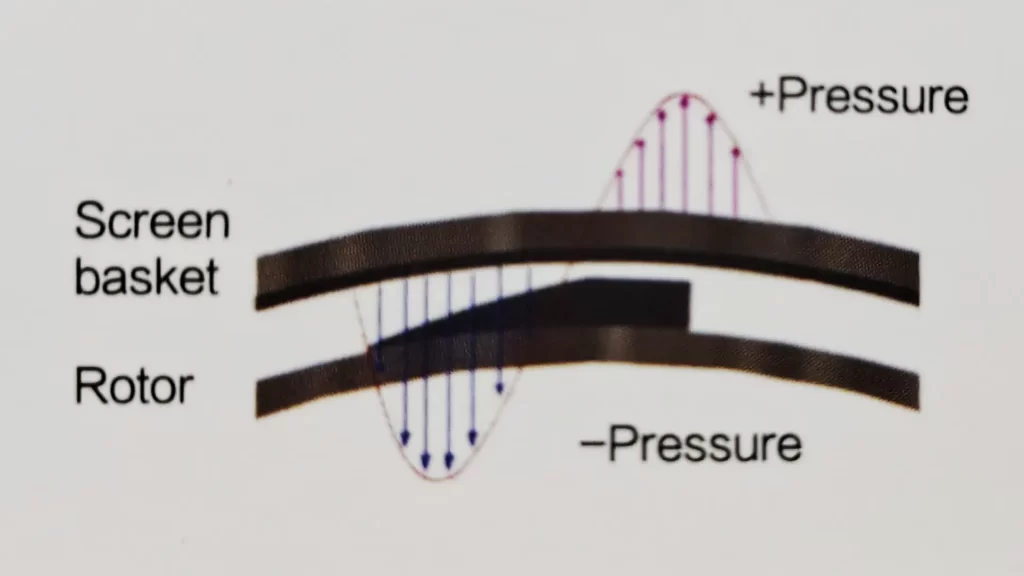

- Multiple Wing Blocks Design for untwisting , gentle pulsating action. Yields clean stock, high pulsation frequency and large capacity.

- Screening under Mid consistency (C <= 4%), reduced water consumption during operation at an obvious energy saving outcome.

- Smaller basket profile without losing design capacity.

- Lower consistency for increased, high screening efficiency extending the overall life of the basket.

- Equipped with an automatic lubrication device and mechanical water seal adapted with a custom monitoring and alarming device.

- Reserved DCS interface (detecting bearing temperatures).

Technical Data:

| Model | ZNS80 | ZNS81 | ZNS82 | ZNS83 | ZNS84 | ZNS85 | ZNS86 | ZNS875 | ZNS87 | ZNS88 | ZNS89 |

| Nominal Area (㎡) | 0.25 | 0.38 | 0.76 | 1.06 | 1.42 | 1.88 | 2.27 | 2.95 | 3.54 | 4.83 | 6.44 |

| Inlet Consistency (%) | 1—4 | ||||||||||

| Capacity-Hole (T/D) | 30-40 | 50-80 | 90-160 | 135-250 | 180-320 | 220-420 | 260-500 | 300-600 | 400-700 | 500-1000 | 800-1500 |

| Capacity-Slot (T/D) | 20-30 | 30-50 | 60-100 | 90-150 | 120-190 | 150-210 | 200-300 | 250-400 | 300-450 | 320-730 | 500-1100 |

| Inlet Pressure (MPa) | 0.2-0.4 | ||||||||||

| Motor Power (kW) | 15-22 | 11-37 | 22-75 | 30-90 | 37-110 | 25-132 | 55-160 | 75-200 | 75-220 | 132-280 | 250-400 |

Applications:

- Impurity Removal: Filters and removes large impurities from the pulp, such as plastics, metal fragments, stones, undispersed wood chips, and fiber bundles.

- Pulp Purification: Improves pulp cleanliness, ensuring the stability of subsequent refining, bleaching, and papermaking processes.

- Equipment Protection: Reduces damage and clogging caused by impurities to downstream equipment, such as refiners, pumps, bleaching towers, and paper machines.

- Product Quality Control: Removes impurities and unqualified fibers, improving the surface quality and physical properties of the paper.

Advantages:

- High Efficiency:Operates under medium-consistency conditions, maintaining high throughput while reducing dilution water usage.

- Low Energy Consumption:Compared with low-consistency screens, medium-consistency pressure screens eliminate additional dilution and thickening stages, thereby lowering overall energy consumption.

- Minimal Fiber Loss:With optimized screen basket design, it efficiently removes impurities while retaining high-quality fibers, minimizing fiber loss.

- Stable Operation:The automatic reject discharge system effectively removes impurities, reducing manual cleaning frequency and ensuring long-term stable operation.

- Low Maintenance Cost:Long service life of the screen basket, compact structure, and easy maintenance.

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project