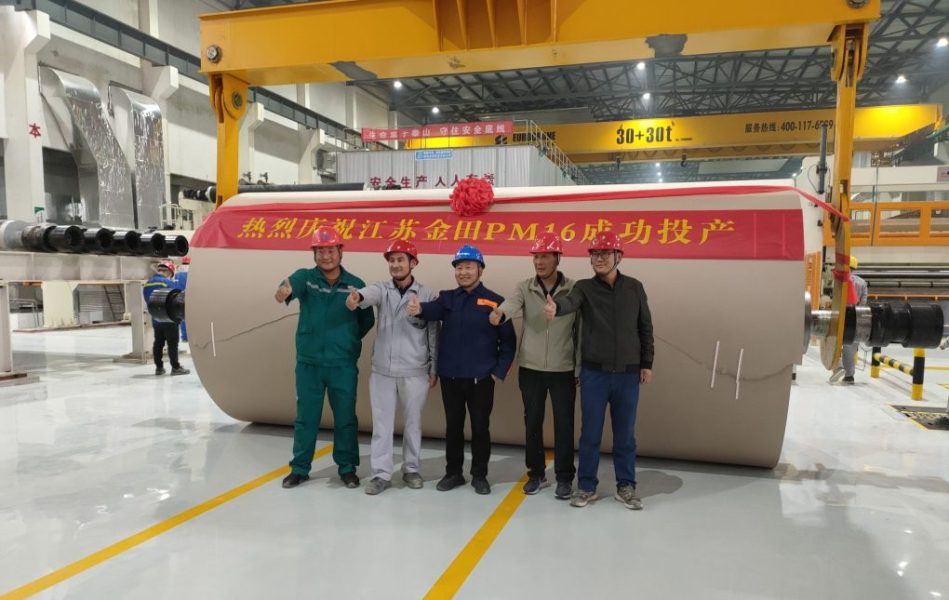

In July 2022, the Stock preparation and approach system provided by Zhengzhou Yunda to Jiangsu Jintian Paper PM16 Line was installed and started up successfully with stable operation.

Yunda provided more than 150 sets equipment for this project, including 6 sets drum pulper, 70 sets screening equipment, 600 pcs cleaner, nearly 20 sets approach system, 4sets ZDG400B drum pulper and 2sets 7.66 ㎡inflow screen is the key equipment.

After the start-up was normal, the project team carried out test and data statistical analysis on the operation. During the test, the waste paper disposal quantity of ZDG400B drum pulper was controlled to be 50t/h~62.5t/h. The pulp quality and the pulp content of discharging slag at the end of drum were excellent, which exceeded the design expectation.

The excellent performance 、professional and enthusiastic after-sales service of Yunda are recognized by Jintian. On this basis, the two parties successfully signed the second phase cooperation agreement .Yunda provides chain conveyor, pulper, HD cleaner , screen plate and other pulping equipment and spare parts for the second phase project.

Project team evaluation:Yunda’s pulping equipment is reliable, efficient, energy-saving and stable.

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project