Zhengzhou Yunda provided a complete set of pulping and approach flow systems for Guangxi Qingyun Paper Industry's 150,000-ton annual production project of tissue paper, which has successfully been put into operation. The system adopts a modular design concept and intelligent control solutions, providing a solid guarantee for the project's efficient and stable operation.

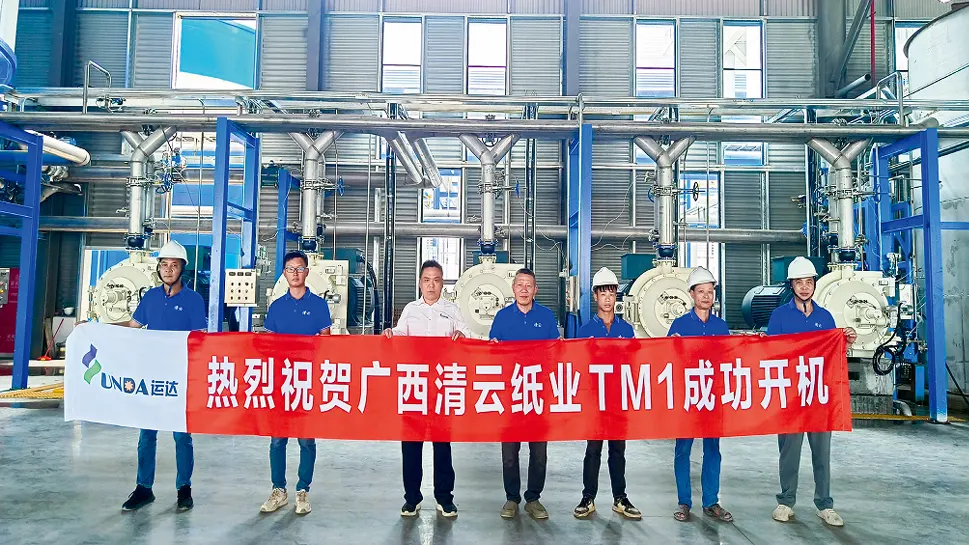

On May 27, Guangxi Qingyun Paper Industry Co., Ltd., located in the Yuegui Circular Economy Industrial Park in Guigang High-tech Zone, successfully produced its first roll of tissue paper from PM1. This marks the successful launch of the company’s first papermaking production line for its 150,000-ton annual tissue paper project and injects new vitality into the paper industry development in the park.

At the same time, the full set of pulping and approach flow systems provided by Yunda for the TM1 production line of Guangxi Qingyun Paper Industry also successfully started operation.

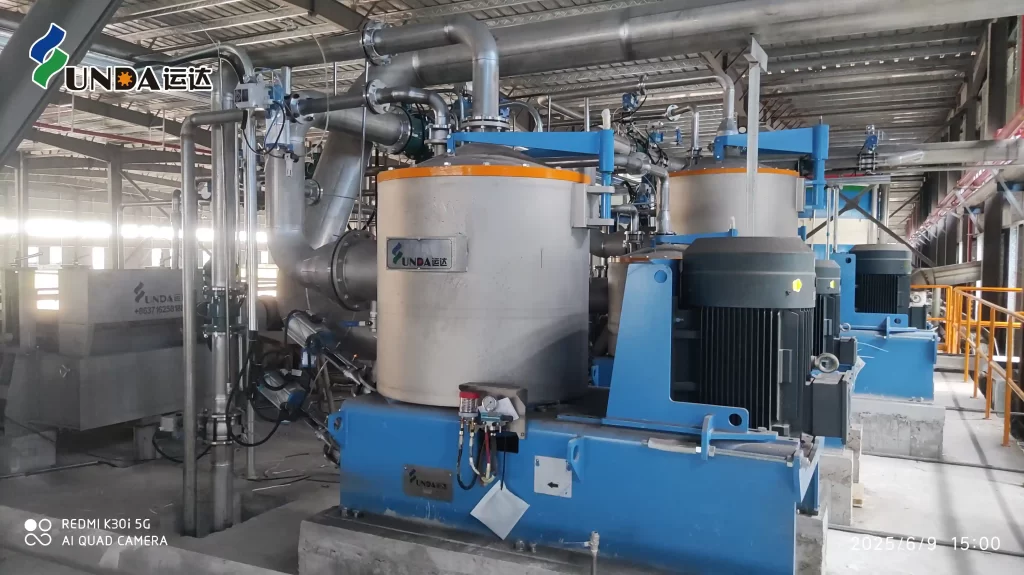

The supply scope includes:

conveying system (Chain conveyor),

pulping system (D-type pulper),

impurities removal system (HD Cleaner),

coarse screening system (mid consistency screen),

fine screening system (super screen),

pulping system (Double disc refiner),

and low pulsation Approach Flow system (Head box screen), etc.

During the project construction phase, Zhengzhou Yunda adhered to the principles of excellence and customer-first. In the design, equipment supply, installation, commissioning, and training stages, Yunda strongly promoted the high-standard implementation of safety production and quality technology measures.

Guangxi Qingyun Paper Co., Ltd. is located in the Yuegui Industrial Park in Guigang City, Guangxi. The company primarily produces tissue paper products such as facial tissues, toilet paper, and paper towels. The successful commissioning of this project injects new momentum into the development of the papermaking industry within the park.

Yunda’s mission: sincerity and intelligence, serving the pulping and paper industry.

Yunda will continue to assist the Chinese tissue paper industry in achieving green production capacity upgrades with reliable, efficient, and energy-saving equipment.