How to correctly operate the double disc refiner (I)

Firstly:

The top priority for startup, running, and maintenance is safety!

Secondly:

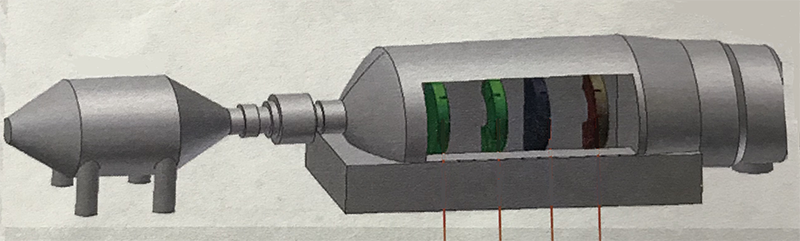

How to use the double disc refiner correctly? Let's learn about it through the following short video:

Thirdly: Install the refiner discs correctly

- Open the refiner housing.

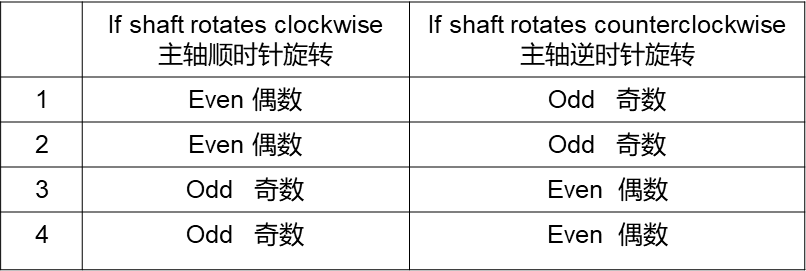

- Looking at the refiner from the adjustment end (opposite to the motor), determine and confirm the rotor rotating direction: clockwise or counterclockwise.

- Remove all refiner discs.

- Clean all rotor and stator mounting surfaces thoroughly.

- Install refiner discs according to the table below.

- Please refer to the Yunda installation manual to apply correct bolt torque.

Fourthly: disc refiner and zeroing

- By the start up or with new refiner discs, the scale should indicate 0. If this is not the case, the scale must be adjusted accordingly.

- Check whether the refiner disc is installed correctly and whether the fixing bolts have been fastened to the torque; Check whether all the discs are in same surfaces and clean the discs; Close refiner door and secure with bolts after inspection;

- Turn the hexagon nut manually to close the gap (it is recommended to use a wrench) and keep turning until it will not turn any further, even if slight force is applied. and the gap between stator and rotor is 0 mm.

- Loosen the hexagonal bolts of the scale, adjust the scale to zero and tighten the bolts

- Retract the gap adjustment device to the 8mm of scale, The indicator light turns on when the limit switch is actuated.

- Manual feed the gap adjustment device until the limit switch indicator light goes out, then retract the device until the indicator light turns on.

- Check whether the ruler scale is -8mm, and readjust it if it deviates significantly.

Notice:

The two hexagon socket bolts need to be locked and checked regularly during normal use to prevent loosening and damage to the gap adjustment device.

How to correctly operate the double disc refiner (Ⅱ)

Note for start-up and normal operation

- 1.Operators need to go to the site regularly to check the operation of the equipment before and after each start-up and shutdown, check the on-site pressure gauge, disc refiner gap value, sealing water flow switch, drain valve, etc.

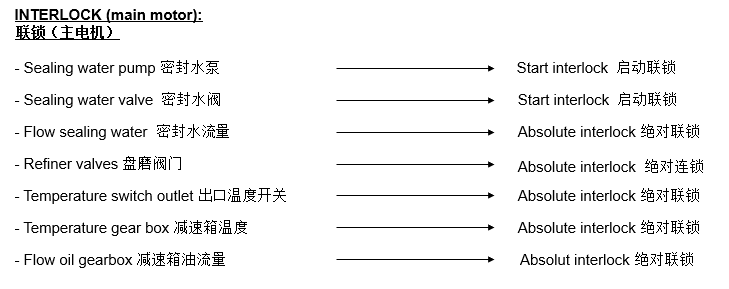

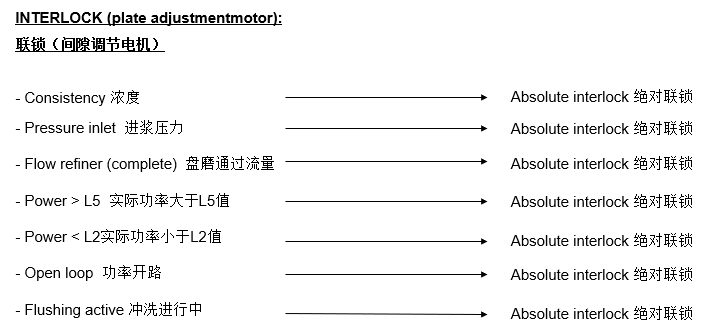

- 2.All motor-related interlocks are not allowed to be released.

- 3.Controlling the beating degree is not just about increasing the power setting of the disc refiner, It can also be achieved by increasing the back flow rate and appropriately increasing the inlet stock consistency (The actual consistency does not exceed 5%), finally increasing the power.

- 4.During normal operation, field inspection must be carried out. When the disc refiner is at zero position, increasing the power will only affect the service life of the disc refiner.

- 5.Adjust the consistency control metering device regularly. the control of disc refiner requires stable and true consistency value.

Start-up and shutdown steps:

Check before starting:

- a,rinse the inside of refiner thoroughly;

- b.well lubricated;

- c. the motor and electrical control system are in good condition;

The start and stop of PM double disc refiner generally adopts group start and group stop methods, and is operated and controlled by DCS.

- Open the PM double disc refiner sealing water device (field hand valve, sealing water signal is normal)

- Open the automatic valves on the inlet pipe and outlet pipe;

- After 5 seconds, check whether it is in the no-load position. If not, The motor of gap adjustment device returns to the no-load position and opens the dilution water valve.

- After 30 seconds, start the main motor; close the dilution water valve;

- After 10 seconds, open the pulp valve in front of the pump and open the consistency control valve to 100%;

- After 10 seconds, start the feeding pump

- After 5 seconds, the consistency control valve switches to automatic mode; if the gap adjustment device is in automatic mode, it will be in automatic mode according to the set value. If it is in manual mode, wait for a signal from the operator.

PM double disc refiner shutdown

- Gap adjustment device with motor moves backwards, After 10 seconds, stop the feeding pump, close the pump front stock valve, open the consistency valve to 100%, and open the dilution water valve. Wait and retract the device to the no-load position;

- After 10 seconds, close the consistency control valve and the dilution water valve.

- After 5 seconds, stop the main motor;

Operation and employee training:

Regular training is very important for employees who have not yet correctly mastered the use of PM double-disc refiners.

In September 2023, the Yunda technical team came to the SUN PAPER site for operational training.

How to use the double disc refiner correctly (Ⅲ)

- Keep the equipment clean

- Add lubricating grease to the bearing every three month, change and cleaning the oil every six month.

- Add lubricating grease to sliding surface between moving pedestal and machine cover every week, change and cleaning the oil every three month.

- Add lubricating grease to trapezoid bolt every three month, change and cleaning the oil every year.

- Add lubricating grease to bearing pedestal every day to keep the good lubrication of sliding sleeve, change and cleaning the oil every year.

- Checking the movement of turntable regularly, if the feed didn’t work well or overload, check the external diameter of the Nylon column pin of coupling. Change it if there is any pit.

Case

-

Guangxi Qingyun Tissue Paper project

Guangxi Qingyun Tissue Paper project

-

Gansu Yusen Tissue Paper

Gansu Yusen Tissue Paper

-

Five Continents Special Paper 450,000 tons packaging paper Project

Five Continents Special Paper 450,000 tons packaging paper Project

-

The i-CTMP High Yield Pulping Production line of Shan Ying

The i-CTMP High Yield Pulping Production line of Shan Ying

-

Shandong Tianhe i-BCTMP pulping line upgrade project

Shandong Tianhe i-BCTMP pulping line upgrade project

-

Guangxi Sun Cultural Paper

Guangxi Sun Cultural Paper

-

Qianan Boda Cultural Paper

Qianan Boda Cultural Paper

-

Vietnam Thuận An Paper PM8 Project

Vietnam Thuận An Paper PM8 Project

-

EG-Paper Packaging

EG-Paper Packaging

-

400t/d Bamboo Fiber i-CTMP Project

400t/d Bamboo Fiber i-CTMP Project