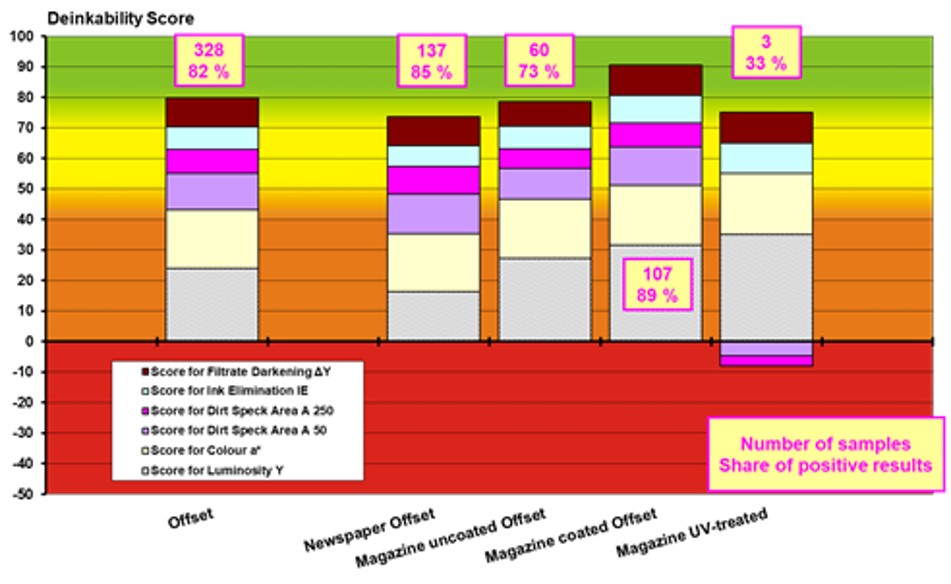

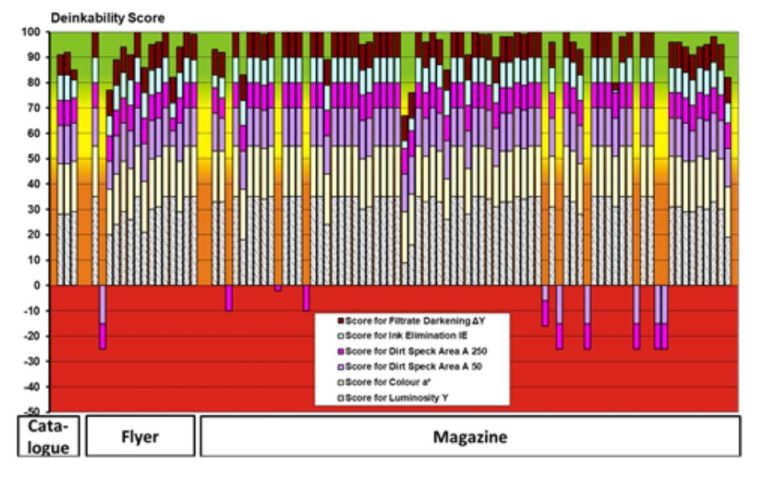

Offset printed products represent by far the largest group in the investigations, comprising 56 % of all tests, mainly newspapers and magazines. Newspapers generally correspond to coldset printing, in which drying occurs primarily by absorption. Flyers printed on newsprint-type papers as well as magazines and flyers printed on SC and LWC papers normally use heatset printing systems for print runs above 50 000 copies. Smaller print runs usually employ sheet-fed offset, in which oxidative drying mechanisms are found.1 Deinkability scores for different offset printed products are presented in Figure 1.

All newspapers examined had been printed by coldset web offset. For offset magazines, the dominating printing process was heatset web offset, and most of the UV-treated prints came from sheet-fed presses. 82 % of the offset prints achieved a positive deinkability score. The following, more detailed explanations will show that, if they fail, it is usually due to luminosity or dirt particle area. The latter often occur in UV-cured prints. Luminosity deficits are found in connection with a high amount of inks on low-weight paper, e.g. with tabloid newspapers, telephone directories and promotional flyers. The variations in the deinkability are more pronounced with uncoated papers.

Coldset offset

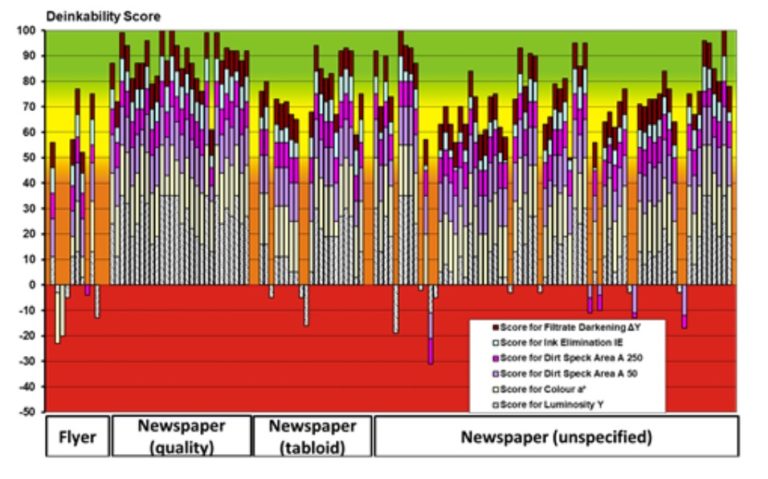

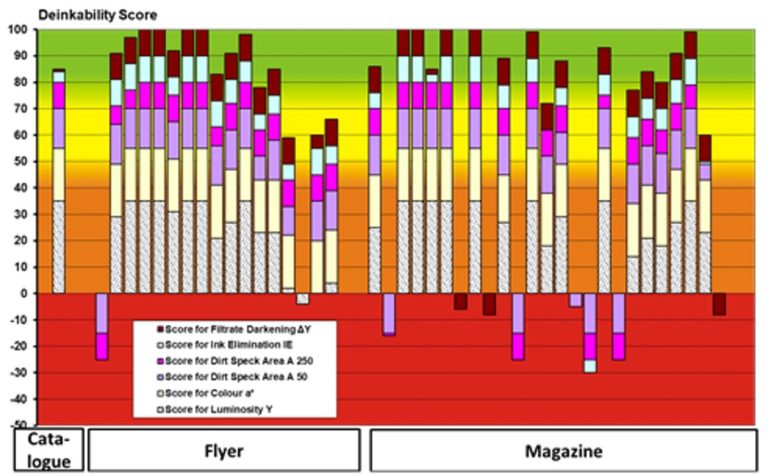

Offset newspapers showed a positive deinkability assessment in 85 % of the cases. If they failed, it was in most cases a matter of luminosity or of dirt specks. Figure 2 illustrates the deinkability results of every individual newspaper, subdivided into quality, tabloid and unspecified newspapers. The figure also shows ten flyers on newsprint-type paper. The columns of the parameters that cause a product to fail extend to the negative score axes. It becomes evident, that 50 % of the flyers fail the test due to luminosity, dirt specks or discolouration of the deinked pulp. In the presentation of individual deinkability results like in Figure 2 positive scores for a print product are not shown, if one of the parameters evaluated obtain a negative score. Then only the one (or more) negative score is shown. It becomes obvious that from the quality newspapers not one failed the deinkability test. Tabloid newspapers sometimes have problems with the luminosity threshold of the deinked pulp.3

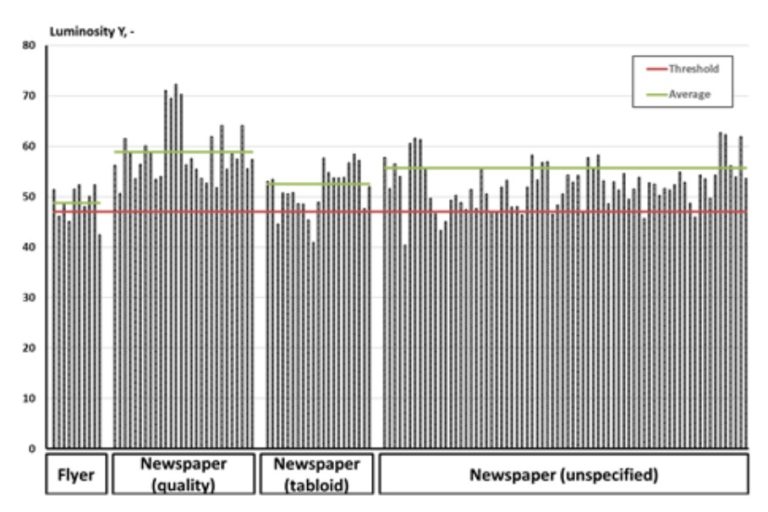

The threshold for the deinked pulp’s luminosity is 47 points for all product categories, except low ink coverage products with a brightness of the base paper above 75 %. If an offset newspaper did not reach this threshold it was, in most cases, only slightly below, as Figure 3 shows with the individual parameter luminosity of the newspapers investigated with the Deinkability Score in the Figure before. The luminosity threshold of 47 is reached by the majority of the examined newspapers, only 12 newspapers fall below the threshold. Most samples by percentage failed in the categories flyers on newsprint and tabloid newspapers, which have a high amount of ink on a low-weight paper. These two categories also had the lowest luminosity of the deinked pulp, 49 for the flyers and 53 for the tabloid newspapers. The unspecified newspapers obtained a luminosity average of 56. All quality newspapers passed the test and the average luminosity was 59. Waterless offset, not especially indicated, was found to be rather trouble-free.3

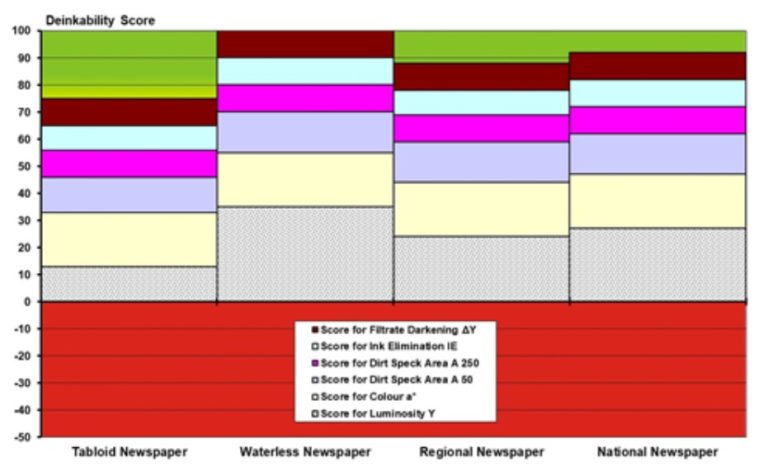

Separate investigations on offset printed newspapers in 2017 confirmed these findings.4 In these experiments not a single print product was tested, but mixtures between 7 to 10 print products from various printing houses, belonging to a certain newspaper category. Printers using a waterless offset printing machine were put together in one category (“waterless newspaper”). Those newspapers were comparable to another category due to their local distribution, named “regional newspaper” but printed by the conventional offset coldset printing process. In addition, two mixtures of nationally sold newspapers, “national newspaper” and “tabloid newspaper”, were tested. In this comparison of tested newspaper mixtures, shown in Figure 4, all results were deinkable, but a clear graduation was found with 75 scoring points for the “tabloid newspaper”, followed by 88 for the “regional newspaper”, 92 for the “national newspaper” and 100 for the “waterless newspaper”.

Heatset offset

Figure 5 shows the deinkability scores of offset printed magazines printed on coated paper and is subdivided in three groups – classical magazines, flyers and catalogues. In many cases, the products received a full Deinkability Score of 100. If coated products fail to achieve a positive score (10 out of 107), this is always due to a high dirt speck area. The huge number of positive deinkability results in the category coated offset magazines (89 % of more than 100 tests) lead to an exception of testing according to the actual version of the EPRC document 5, provided that the ink composition used, fulfils the documented specifications.

Individual offset print products on uncoated paper (Figure 6) show a somewhat poorer deinkability behaviour. Also 10 products failed the test, but the total number of tests is with 60 significantly lower. Also for uncoated paper the main reason for failing the test is also dirt specks, but also filtrate darkening and in one case too low luminosity are reasons for missing a positive Deinkability Score. As a result offset heatset prints on uncoated papers have no exception for testing deinkability according to EPRC until now.

UV Heatset offset

Traditionally, UV-cured inks and varnishes find their major application in high-quality packaging. Their use in graphic products is limited to prints which need a higher mechanical resistance than standard offset or for gloss effects. Recently new applications have emerged: utilisation of newsprint presses for printing brochures during daytime hours when the presses are usually idled. Getting the inks dry is the major challenge in this respect. Since the coldset presses do not have drying equipment and the installation of heat dryers is not feasible, UV is one way to overcome this issue. Other advantages besides, include a very rapid double-sided printing and drying technology, the high quality of the printing results, no necessary powdering and no solvents or mineral oil containing inks.6

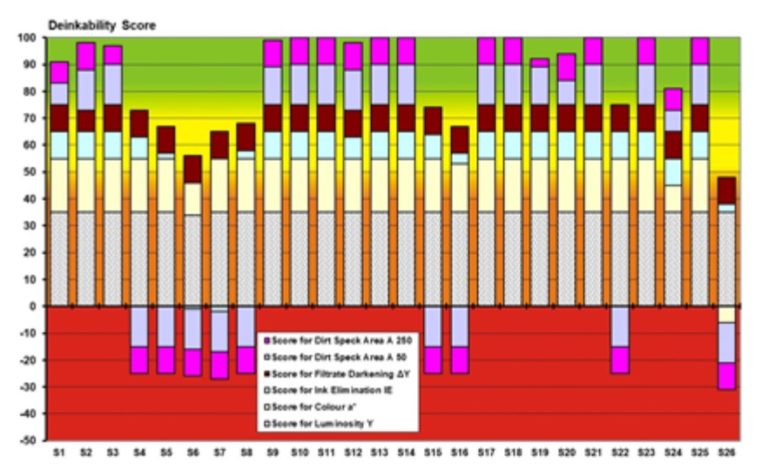

In a recent research project on the deinkability of UV offset prints, an inventory was made in 2019 with 26 commercial print products from German print shops. The deinkability results are seen in Figure 7. About one third of the investigated samples were assessed as not deinkable. As expected, the critical criteria for UV ink are the residual ink dirt specks in the deinked pulp of each sample, as it is shown in the Figure. In rare cases additionally the colour value (S 26) or the ink elimination (S 6 and S 7) may be critical. The problem with too large ink specks becomes clear when the cross-linking (polymerisation) of the ink film is considered, which makes the ink film resistant to abrasion, one of the advantages of UV printing. This survey also makes clear that there are already samples on the market which cause no problems in deinking. Correlation between paper grades used and printing and drying conditions are not yet available. The project is not yet finished and with pilot printing studies the influencing factors will be examined to improve the deinkability of UV print products further.

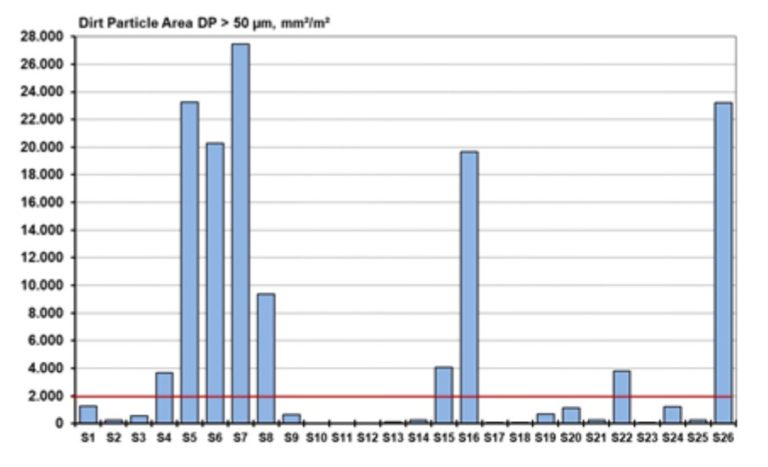

As one example, the dirt speck areas of all particles above 50 µm circle equivalent diameter are shown in Figure 8. It becomes obvious that from the 9 samples failing the parameter, one third are about twice above the threshold of 2 000 mm²/m². The other 6 samples are above the threshold by a factor of 5 to 13.

Source https://forestbiofacts.com/

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project