Jingcheng Intelligence, serving the pulping and papermaking industry.

Late-night urgent call, rapid deployment for assistance.

On the evening of June 6, 2025, at 19:17, the on-duty staff of Yunda Project Management Department received an urgent call from a factory. The PM26S double disc refiner supplied by our company suddenly malfunctioned. The Yunda emergency service team quickly mobilized, bringing spare parts and measuring instruments, and rushed to the customer's factory.

Peeling away the layers to diagnose precisely.

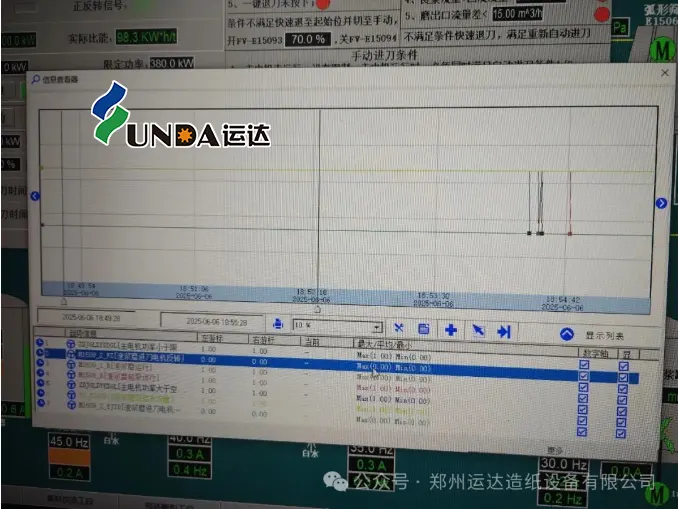

At 8:50PM on the same night, the Yunda emergency service team arrived at the customer's site. After analyzing the DCS curve records, electrical engineer Pan Jundi discovered that the reversal signal of the feed motor was always 0, meaning the DCS system continuously output a forward rotation signal without any reversal signal. This was likely the direct cause of the malfunction.

However, why was this signal always 0? Pan Jundi conducted a system simulation test to observe if the issue would repeat. The Yunda emergency service team engineers jointly analyzed the DCS program and discovered that the proximity switch signal from the disc position was constantly causing the DCS system to output the forward rotation signal. Upon reviewing the curve, it was found that the proximity switch signal was absent before 6:00 AM, but around 6:00 AM, the signal began to flicker intermittently before remaining constant. The engineers then investigated the cause: after removing the proximity switch on-site, the signal remained; however, after disconnecting the DCS wiring, the signal disappeared. This indicated that the issue was with the intermediate wiring.

Battle at dawn, escorting to the end.

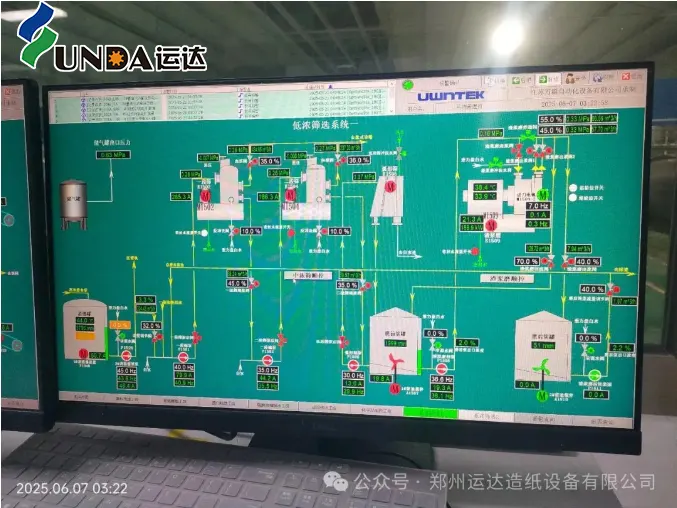

Following the clues, the Yunda emergency service team conducted a thorough inspection of the cables. In the early hours of the morning, the fault point was finally found: a short circuit in the signal cable inside the cable tray caused the malfunction.

After replacing parts, repairing the wiring, and restarting the equipment… when the production line roared back to life, the clock had already struck 3:22 AM. However, the Yunda team did not leave. Instead, they stayed on-site for another two hours, observing until they confirmed that production had stabilized completely.

Professional integrity, mission commitment.

The Yunda emergency service team performed outstandingly during this service, resolving the issue with precision and speed, earning praise from the customer. They once again embodied Yunda’s corporate mission of 'Jingcheng Intelligent Services for Pulp and Paper.

Company Profile

Zhengzhou Yunda Paper Machinery Co., Ltd. was established in 1981 and is a competitive manufacturer of complete pulping equipment and conveying systems in China. The company’s business involves pulping and papermaking, paper mill waste sorting, and urban solid waste sorting, providing engineering design, equipment, and services for these industries.

Domestic Sales Phone: 0371-62581888

International Sales Phone: +86-371-62581860

Email: info@yundapm.com

Headquarters Address: No. 168, Century Avenue, Xuedian Town, Xinzheng City, Zhengzhou, China

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project