The pressure screen rotor and pressure screen basket are both essential components required for the operation of pressure screens.

The screen basket is a wearing part. The Oda screen basket produced by Yunda is made of stainless steel, which is wear-resistant and corrosion-resistant. The surface of the slurry-facing part is treated with electroplated chrome for higher strength and greater resistance to wear and corrosion, effectively resisting the erosion of sand and impurities. This significantly extends its service life, reduces replacement and maintenance costs, and ensures maximum efficiency.

The screen basket comes in two structural forms: plate-type corrugated screen basket and rod-type corrugated screen basket .

The screen plate of the plate-type corrugated screen basket is made of stainless steel and comes in two types: perforated and slotted. The surface of the screen plate in contact with the slurry is provided with corrugated grooves, which help fibers pass through the screen holes (slits) more easily. This effectively separates qualified fibers from impurities and fiber clumps, improving the screening efficiency and resulting in high-quality pulp. The screen plate is made with drilled holes or milled slits and is polished for a smooth surface. The surface of the screen basket is highly polished, and an reinforcing ring is welded to the outer surface of the screen basket, providing sufficient strength and rigidity. The upper end has a flange, which is bolted to the cylinder body, while the lower end rests inside the shell, ensuring a firm connection and stable operation.

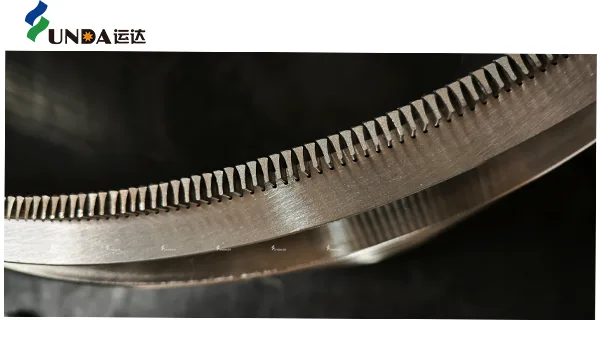

The structure of the rod-type corrugated screen basket consists of hundreds of special wedge-shaped bars, which are evenly embedded along the circumferential grooves of multiple annular plates. The upper end features a flange surface, which connects to the cylinder body, while the lower end is conical. The surface of the screen basket is corrugated, and the screen slots can be finer and more precise than those in the milled-slot plate structure. The open area is significantly increased, and the strength of the rods is much higher than that of the milled-slot plates. Especially after surface hardening treatment, the screen basket has a longer service life. This is one of the most advanced structural forms in the world today.

The history of the Oda screen basket

Zhengzhou Yunda established the Yunda Intelligent Equipment Research Institute and its Precision Screening Technology R&D Center in 2019, leveraging a wealth of data and experience accumulated from years of use and research to further develop and innovate screen basket technology. In the same year, Yunda also founded its wholly-owned subsidiary, Oda Intelligent Equipment (Zhengzhou) Co., Ltd., to create the Oda screen basket brand, specializing in the research, development, and manufacturing of Oda screen baskets.

Yunda has been granted 282 authorized patents, including 20 authorized invention patents:

- Auxiliary device for welding the positioning block of the screen basket in the medium-consistency pressure screen body: ZL201821090653.3

- Roll-type rod screen basket: ZL201922382416.5

- Manufacturing device for the filter support of the screen basket: ZL201922467243.7

- Welded-type internal and external screen basket with rods: ZL201922379029.6

- Cutting tool for the positioning groove of the pressure screen basket: ZL202022906604.6

- Expansion sleeve top seam tool for pressure screen baskets: ZL202023155253.6

- Step rod screen basket with interference bars: ZL202123406997.5

- Pencil holder: ZL202130457667.5

Features of the Oda screen basket.

1.Energy-saving.

- Taking the wedge-shaped bars width of 2.5mm and the slot width of 0.15mm as an example (as shown in the figure), compared to traditional bars, the Oda screen basket increases the open area by 11.8% with the same slot width. That is, the open area increases by 11.8%. According to the formula Q≡V*S, when the slurry flows through the screen slots at the same velocity, the larger open area of the Oda screen basket allows for a higher throughput of good pulp. Therefore, using the Oda screen basket can improve production capacity and reduce energy consumption.

2.High-efficiency.

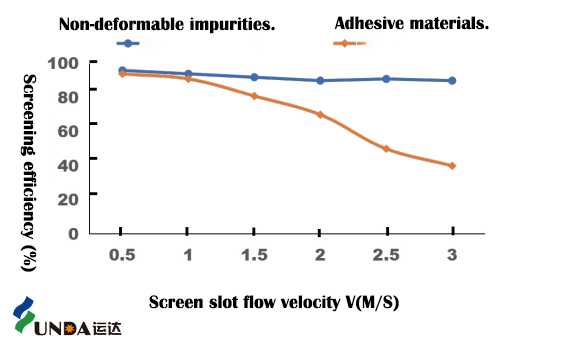

- Compared to traditional bars, the Oda wedge-shaped bars increase the open area by 10-13% with the same slot width, meaning the open area increases by 10-13%. According to the formula v = Q/S, where v is the slurry flow velocity through the screen slots, Q is the good pulp flow rate, and S is the open area of the screen basket: As shown in the figure, when the good pulp flow rate is constant, the larger the open area of the screen basket, the lower the flow velocity through the slots, which results in higher adhesive removal efficiency.

3.Long lifespan.

High screen basket strength.

- The bars of the Oda screen basket are arranged in a stacked configuration. Under the same slot width conditions, the greater number of bars results in higher screen basket strength, thereby extending the service life of the screen basket.

Imported wedge-shaped bars.

- The material used is SUS304 or SUS316L (optional).

- The surface of the bars is coated (thickness 100-250um, depending on the process location), which can:

- Increase the wear resistance of the bar surface, thereby extending the service life of the screen basket;

- Enhance the corrosion resistance of the bar surface;

- Improve the smoothness of the bar surface.

| Screening area | Screening consistency | Common aperture size | Common screen slot size | Fine screening slot width |

| 0.4m²-12m² | 0.1%-1%(Specific pulp types 1.6%) | Ф1.4mm-2.0mm | 0.15mm-0.6mm | 0.05mm-0.15mm |

Provide a rotary drum-type internal flow screen basket for the coarse screening section (wastepaper pulp line perforation range: Ф1.2mm-3.0mm, chemical pulp line perforation range: Ф3.0mm-12mm).

Outflow-type pressure screen basket

| Screening area | Common slot width range for waste paper pulping coarse screen | Common aperture size range for waste paper pulping coarse screen section | Common slot width range for waste paper pulping fine screen | Slot width range for chemical pulp and mechanical pulp fine screening |

| 0.25m²-10.6m² | 0.35mm-0.6mm | Ф1.4mm-2.4mm | 0.15mm-0.25mm | 0.10mm-0.25mm |

Additionally, Yunda also provides black liquor over-screening baskets (Ф0.12mm-0.20mm micro-perforated screens) for fiber recovery in chemical pulp and mechanical pulp lines.