Similar to virgin fibres, recycled-fibre stock must meet defined quality criteria for a given furnish. ln this sense, quality refers to the fibre characteristics, such as the type and condition of fines, and to additives and contaminants. Recycled fibre processing systems are significantly more complex than virgin-fibre systems for two reasons. First, the recovered paper usually is a mixture of various fibres or paper grades. More importantly, it also contains a certain proportion of contaminants and other detrimental substances. These are classified as follows according to their origin:

- additives used in previous paper production process, such as fillers and dyes, coating components, and functional and process chemicals

- substances added according to the application, such as printing inks, coatings, foil laminates and adhesives materials mixed with the paper during its life cycle and subsequent collection, including wires and strings, sand and stones, or paper clips and folders.

Within wide regional variations, recycled fibres partly, largely, or completely replace the various kinds of virgin fibres in many paper and board grades today. Recycled fibre is called “urban pulp” and its utilisation is essential for a sustainable production. Fibre quality and cleanliness have comparable demands. For example, fibre quality determines mechanical paper characteristics and printability. Cleanliness covers optical, chemical, colloidal, microbiological, and processing aspects such as sand and stickies

The selection and monitoring of the recycled fibre furnish play a very important role in cost-effective recycled fibre processing and in maintaining adequate quality of the finished stock. The primary tasks of processing are to remove contaminants and eliminate their effects, or both, as much as necessary to meet quality requirements.

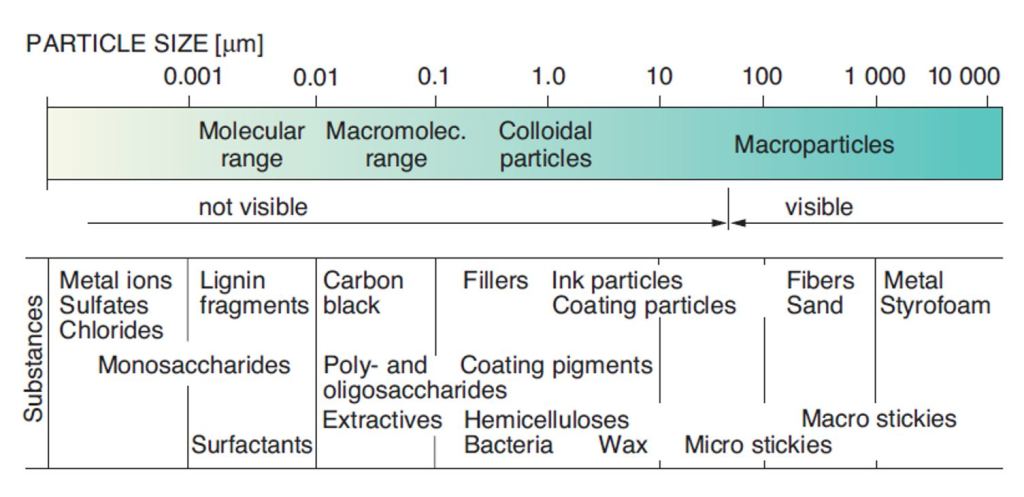

Figure 1 shows an overview of some substances encountered in recycled fibre pulps with their approximate particle size ranges. The extent to which they need to be removed depends on how much they interfere with paper manufacturing or product quality requirements.

Separation processes vary according to the type and quantities of contaminants to be removed. The separation criteria involve certain characteristics of these materials that need to be clearly distinguished from fibre characteristics. These include the size, shape, deformability, density, and surface properties of the particles influencing flotation and sedimentation. Table 1 summarises the characteristic particle size and specific gravity of some typical contaminants

Table 1. Particle size and specific gravity of contaminants in recycled fibre processing

| Type of contaminant | Specific gravity (g/cm3) | Particle size (m) | ||||

|---|---|---|---|---|---|---|

| <1 | <10 | <100 | <1000 | <1000 | ||

| Metal | 2.7–9 | x | ||||

| Sand | 1.8–2.2 | x | x | x | x | |

| Fillers /coating particles | 1.8–2.6 | x | x | x | ||

| Ink particles | 1.2–1.6 | x | x | x | x | x |

| Stickies | 0.9–1.1 | x | x | x | x | x |

| Wax | 0.9–1.0 | x | x | |||

| Styrofoam | 0.3–0.5 | x | x | |||

| Plastics | 0.9–1.1 | x | x | x | ||

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project