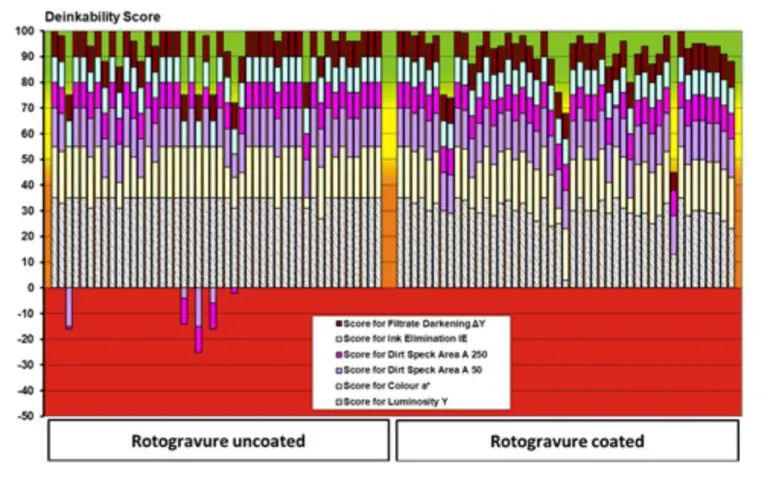

As already seen in the overview on printing technologies, rotogravure prints are easily deinkable in general, as shown in Figure 1. From almost 100 tests, 95 % achieved a positive deinkability result. The few which failed in the test were uncoated magazines and failed due to dirt particles. Red discolouration was in some cases visible but just within the threshold corridor, so it did not lead to negative assessments. This is an improvement compared to older results and lead for rotogravure printing products on uncoated and coated papers to an exception of deinkability tests, provided that the ink formulation is within the mentioned specification according to the EPRC document.

The main use of flexographic printing is for packaging products. Inks are either solvent- or water-based. In graphic products, some newspapers in Italy and the UK are printed in water-based flexographic printing. All tests failed in luminosity, ink elimination and filtrate darkening due to the hydrophilic nature and the size of the ink particles: 0.01 µm to 5 µm as the total range and 0.05 µm to 1 µm as the main range.1

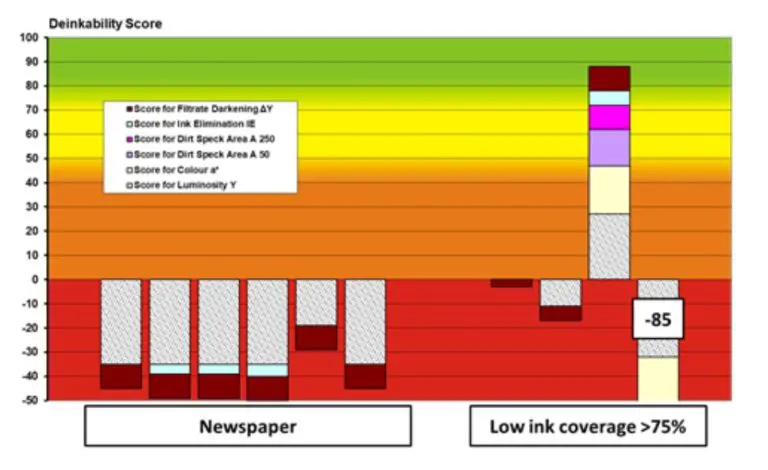

Figure 1 shows to the left the detailed results of commercial flexo printed newspapers of the deinkability survey 2, which did not differ very much. On the right hand side are some results shown which belong to the category of low ink coverage product with brightness of base paper above 75 %. Newly developed inks can perform significantly better. The use of these types of inks would be a significant progress in deinking of flexo printed newspapers, but they are not yet commercially established.

There are observable deficits in the optical properties of the deinked pulp and the process filtrate if the content of flexo printed newspapers in the raw material exceeds 2 %. In a few cases, the deinking process can be tuned a little to cope better with flexo, but usually at the expense of a lower efficiency in the removal of other ink types present in the recovered papers blend. 4 A prerequisite for this is the operation of a two-loop deinking process. The pH in the first loop has to be lowered since the flexographic inks fragmentise too much in alkaline conditions. The first deinking loop then has a slightly higher efficiency in flexo ink removal. The alkaline chemistry which is required to remove the standard offset and rotogravure inks has to be introduced later in the process. The disperser and second deinking loop take over some tasks of the first loop, thus limiting a plant’s capability to producing standard deinked pulp grades. Moreover, it increases the tolerance of the amount of flexo printed products only slightly. The introduction of better deinkable inks is therefore essential.

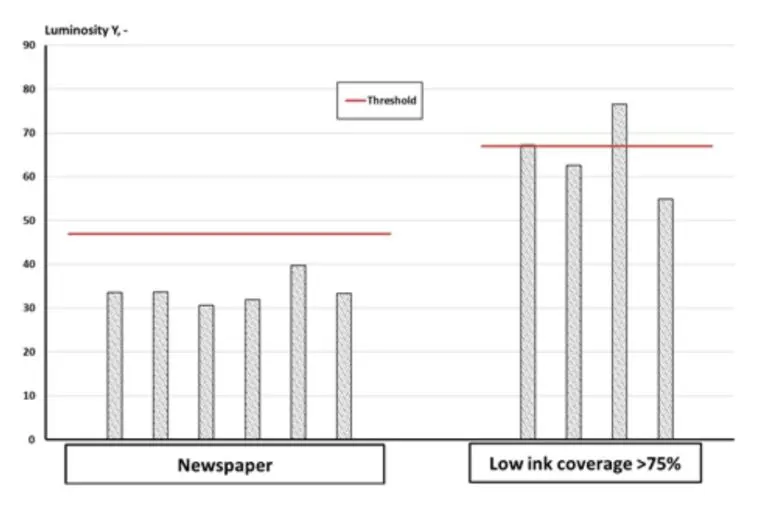

The dilemma with water-based flexo printed newspapers becomes obvious with a view on the parameters luminosity and filtrate darkening. For the commercial flexo newspapers luminosity was in a range between 30 and 40, as shown in Figure 2. In comparison, the majority of offset printed newspapers exceeds the luminosity threshold of 47. This is a typical luminosity difference of more than 10 points. For the low ink coverage product category with a brightness of the base paper above 75 % the threshold increases to 67, due to the high base paper brightness. From the four test samples, two products (50 %) fall below the threshold, one touched it and one came in above the threshold.

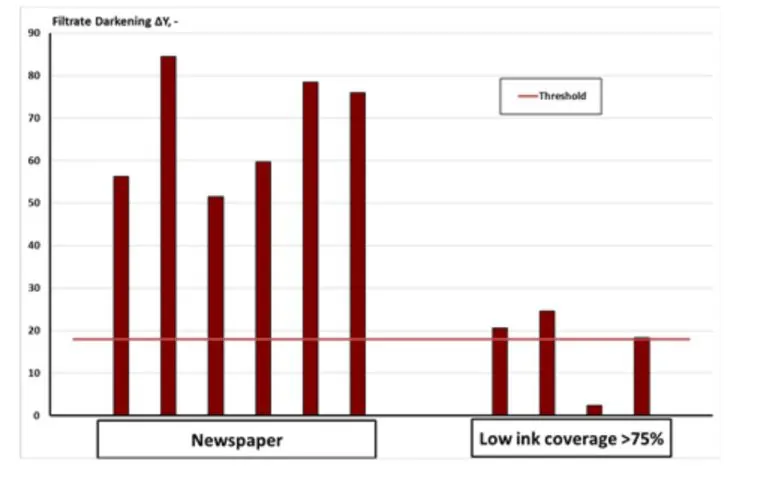

The filtrate darkening threshold of 18 points is for all print products identical. For the tested offset printed newspapers this threshold was no challenge. For the commercial flexo newspapers filtrate darkening is significantly higher in a range between 51 and 85 points, as it is shown in Figure 3. For the low ink coverage products only one of the four products was below the threshold. The average of these products is with approx. 17, significantly lower than for the flexo newspaper with an average filtrate darkening of 68.

Source https://forestbiofacts.com/

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project