The D-type pulper vs drum pulper are both important equipment used in paper mills for pulping waste paper. So, how should paper mills choose the right pulping equipment? Below, we will make a comparative analysis of the differences between the D-type pulper and the drum pulper. We hope this will help you have a clearer idea when selecting a pulper.

Let's first take a look at the technical specifications of both.

| D-type pulper | drum pulper | |

| Area: | Smaller | Larger |

| Capacity (T/D): | 20-1500 | 70-1300 |

| Motor Power: | 75-1120 | 132-1250 |

| Energy Consumption: | Average | Lower |

| Pulp Consistency: | Low (3-5%) | High (10-17%) |

| Raw Materials: | Waste paper, waste cardboard, paperboard, Recycled fiber processing | Waste paper, waste cardboard, paperboard, Recycled fiber processing |

| Operation: | Strong pulping, continuous impurity removal | Gentle fiber treatment, continuous operation |

Here is a more detailed comparison.

D type pulper

The D-type pulper is relatively more flexible in use. Due to the unique D-shaped tank structure, it enhances the vortex effect, allowing the paper bales to be quickly soaked and improving pulping efficiency. The D-type reactor structure changes the flow of the pulp, accelerates the contact between the rotor and the pulp, shortens the pulping time, and increases the capacity. Meanwhile, impurities are twisted into rope-like forms under the vortex action and are continuously or periodically extracted by the ragger and rope cutter.In the continuous pulping system, impurities can be cleared in time, reducing the chances of impurities being finely shredded. This eliminates the need for frequent stoppages to clean impurities, improving the overall operational efficiency of the pulping system and reducing energy consumption.

The D-type pulper is suitable for capacities ≥30TPD. It is ideal for processing waste paper such as cardboard, newspapers, and paperboard. The resulting pulp can be used to produce newsprint, cartons, corrugated paperboard, etc.

Advantages:

- Strong pulping capacity, with the pulp consistency evenly circulating in the tank at 3%-5%.

- Suitable for a variety of raw materials, especially ideal for OCC, waste paper, waste paperboard, etc.

- For the same capacity, the equipment investment is lower than that of a drum pulper, resulting in lower costs.

- Small footprint, lower land investment, and reduced construction costs for the production line.

Disadvantages:

The energy consumption of the D-type pulper is slightly higher than that of the drum pulper. Due to its strong pulping capacity, the subsequent impurity removal process requires greater capacity, and the processes for increasing pulp consistency and concentration also need to be specially designed. We, at Yunda, offer professional OCC solutions, which you can also refer to.

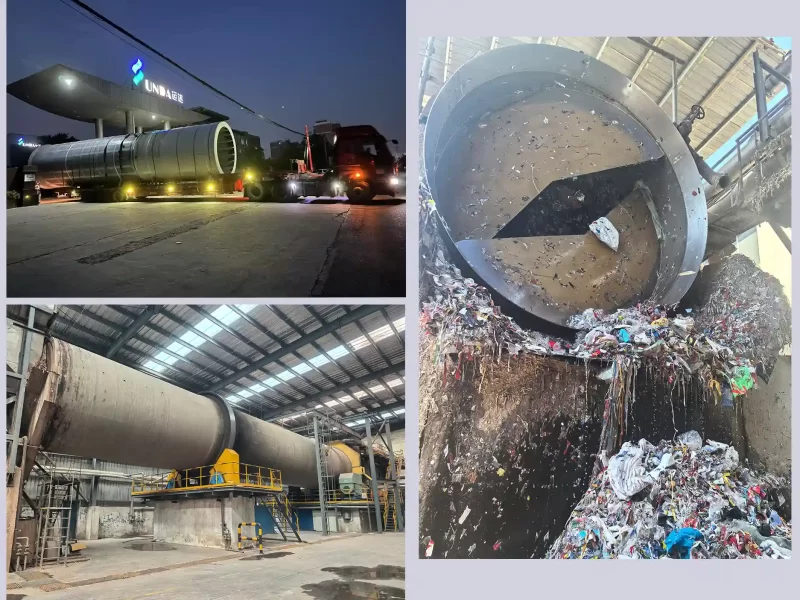

Drum Pulper

The drum pulper combines both pulping and coarse screening functions. Waste paper enters the mixing and pulping sections of the drum pulper, where it is gently disintegrated through the internal special shape, without cutting force or severe shear, preserving the highest physical properties of the fibers and minimizing damage to long fibers. In the screening section, the pulp is diluted by spray water, and the qualified pulp flows into the bottom pulp pool for further processing. Waste plastics are washed and discharged through the waste outlet. The drum pulper is suitable for capacities ≥80TPD, commonly used in packaging paper production lines, and also applicable for large-scale production of cultural paper, tissue paper, and other types of paper.

Advantages:

- Compared to the D-type pulper, the drum pulper has advantages such as a simpler system, lower energy consumption, and lower maintenance costs.

- It causes minimal damage to impurities, especially to adhesives, films, and other contaminants, reducing wear on subsequent equipment.

- The impurity breakage rate is low, and slag discharge efficiency is high. Impurities are discharged at concentrations of 10-17%, reducing the load on downstream equipment.

- The disintegration retention time is long, allowing for thorough fiber separation.

- It preserves fiber characteristics and minimizes contamination damage, supporting continuous operation and suitable for various grades of recycled materials.

- With fewer wear parts, the maintenance cost is low.

- It can handle all grades of recycled fibers.

- The machine operates continuously without downtime, running 24/7 and reducing maintenance costs.

Disadvantages:

- The disadvantages include a large footprint, which requires significant investment in plant and infrastructure construction.

- It is suitable for large and stable production capacities. Once the equipment is selected, there is little room for adjustment, and the waste paper raw materials and production capacity need to be relatively stable.

- It cannot handle materials that are difficult to disintegrate, so the selection of raw materials needs to be carefully screened.

The drum pulper and D-type pulper provided by Yunda are made of high-quality materials, feature excellent quality, advanced technology, and are benchmarked against top international standards, offering excellent cost-effectiveness. If you need these equipment, please contact us for more discounts and quotations.

E-mail: info@yundapm.com

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project