Brief:

The plug screw feeder is mainly used in the chemical thermal mechanical pulping system and MDF production line. The plugging before T-piece unit for sealing the tube so as to avoid pressure loss at the rear end.

Structure:

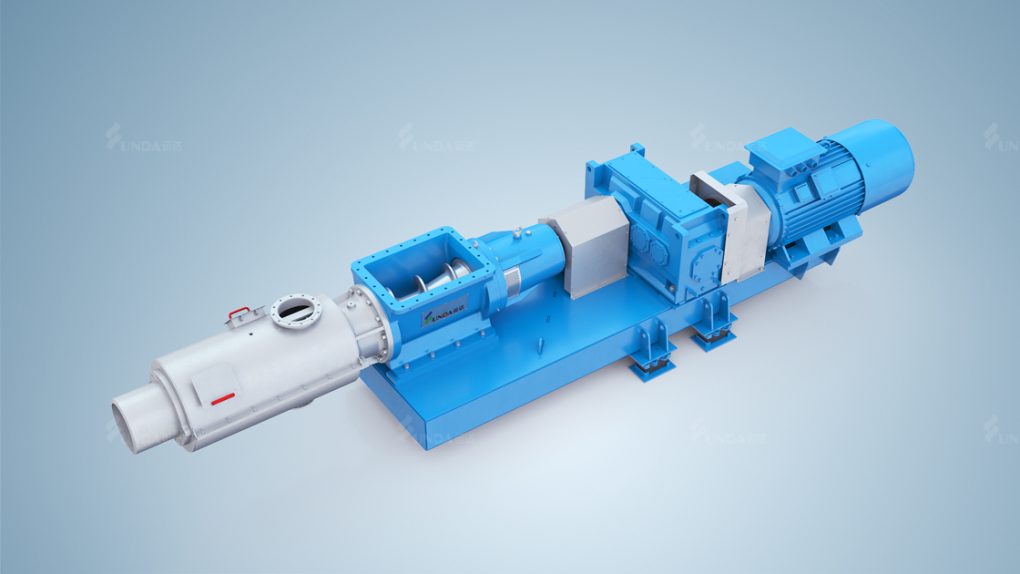

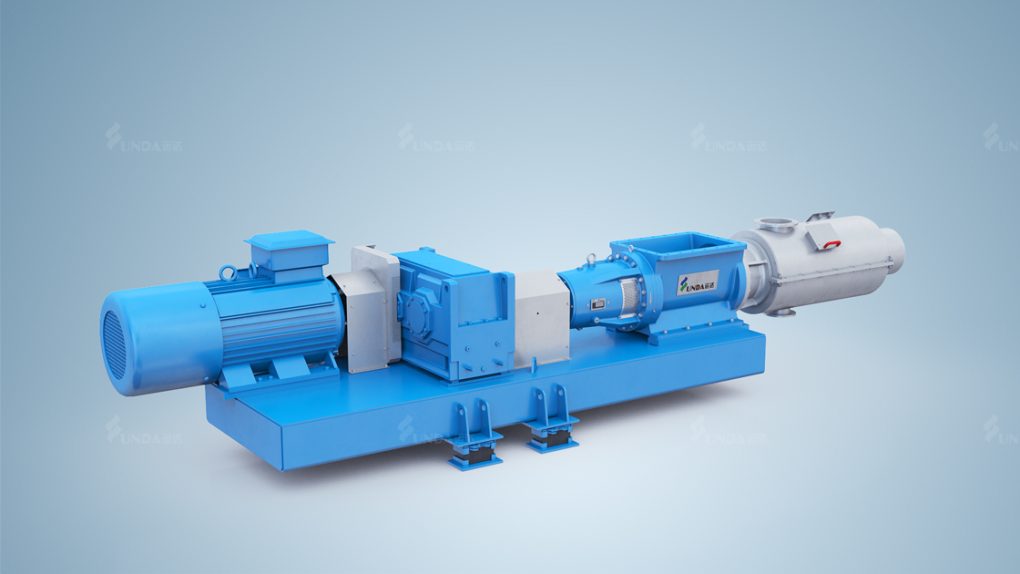

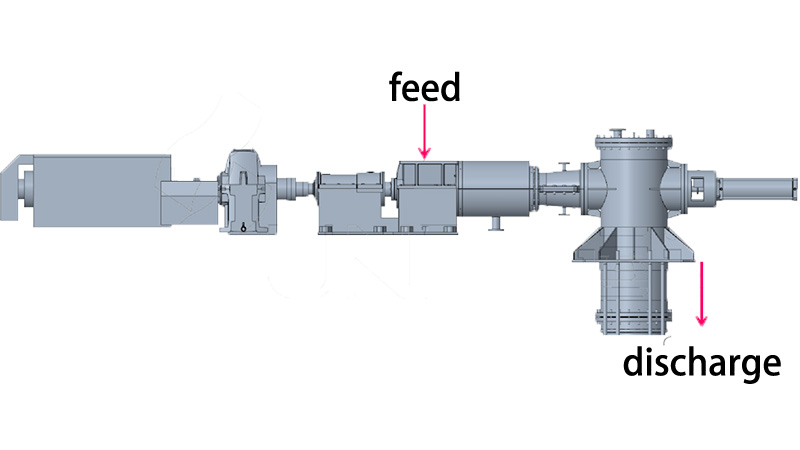

The main components of the plug screw feeder consists of bearing chamber, feeding case, feeding screw, sleeve pipe, conical plug pipe and dewatering section unit. The filtrate collection cover device is installed on outside of the separated conical plug pipe and dewatering section unit.

Advantage:

- The plug screw feeder has high transportation efficiency

- provides reliable runnability and operates safely,

- which has the characteristics of simple structure,

- multi and complete functions,

- good performance of internal sealing ,

- low noise and good appearance etc.

Operation principle:

The wood chips are conveyed and pushed into sleeve pipe and plug pipe by screw feeder, and formed to be material plug which is used for sealing the T- piece unit so as to keep the pressure at the rear end. There are wear-resistant and anti-skid strips on the sleeve pipe and plug pipe to prevent the material plug from rotating with the screw feeder.

Model & data

| Model | WLQ20 | |||

| Runnability | kwPower of Configuration | 400 | ||

| rpmMain body rotating speed | 70 | |||

| Size | mmMain Body Length | 4800 | ||

| mmScrew Length | 2700 | |||

| mmScrew Diameter | 500 | |||