The removal ability of adhesive applications is another product related quality aspect of paper products. Adhesive applications may form tacky particles, so-called stickies, in the paper recycling process. In graphic paper, the most visible components are glued spines of books, catalogues and magazines, glued inserts in magazines, labels of all kinds and the sealing of envelopes. Stickies are classified according to their sources as primary and secondary stickies.1 The first group of stickies is introduced in the recycling process by the individual paper products with the paper for recycling. Secondary stickies originate from physico-chemical effects during processing of paper for recycling. Depending on their size, stickies are classified in macro, micro and disco (dissolved and colloidal) stickies. There is a clear definition to distinguish between macro stickies and micro stickies based on a mechanical screening process at laboratory scale. The definitions of discostickies are not as clear and generally acknowledged.

It is well known that there is always a huge quantity of stickies with a particle size below the detection limit of macrosticky methods.2 Even if these small stickies are not excessively disturbing, they have enormous potential to create problems in the papermaking process. If they are not removed by screening – which is difficult or even impossible due to their small size – or properly fixed, they often agglomerate and form larger secondary stickies, which frequently cause runnability problems on the paper machine or paper quality defects.

Research work has proven that mechanical screening is the most efficient tool for sticky separation in the industrial process. High sticky removal efficiency is important for all paper recycling processes – for packaging papers and board as well as for graphic and hygiene papers. From the point of view of recyclability, stickies have to stay as large as possible to allow them to be screened. A proper assessment of the sticky removability has to consider the different key conditions of the paper for recycling processes.

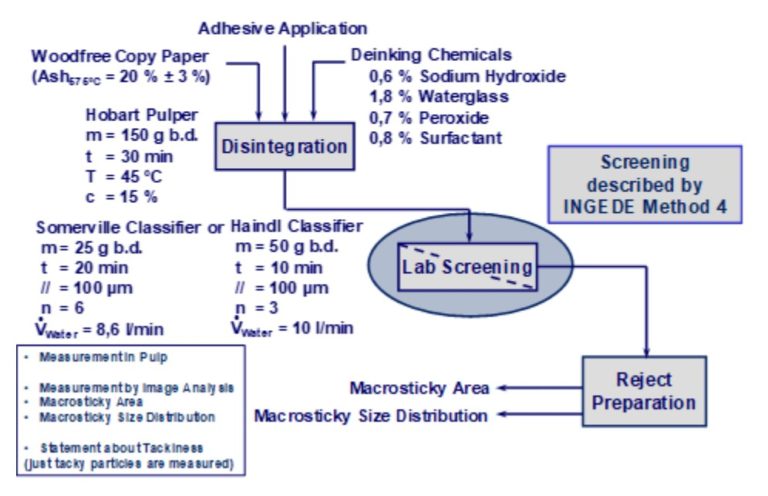

The procedure for measuring macro stickies in pulp is described in INGEDE Method 4 and can be used for any recycled fibre pulp in general.3 This analysis is based on a laboratory screening procedure, where the reject is prepared after screening in such a way that adhesive impurities can be detected by a scanner-based image analysis system. The method finds its application in mill control procedures as well as a part of assessment method for the removability of adhesive applications in INGEDE Method 12.4 This method includes the pulping procedure of a graphic paper product in an alkaline environment and simulates the fragmentation behaviour of adhesive applications during paper for recycling processing in a deinking mill. This method as well as the assessment is very often also used for packaging products, but without verification whether the transferability to this different paper product category is permissible.

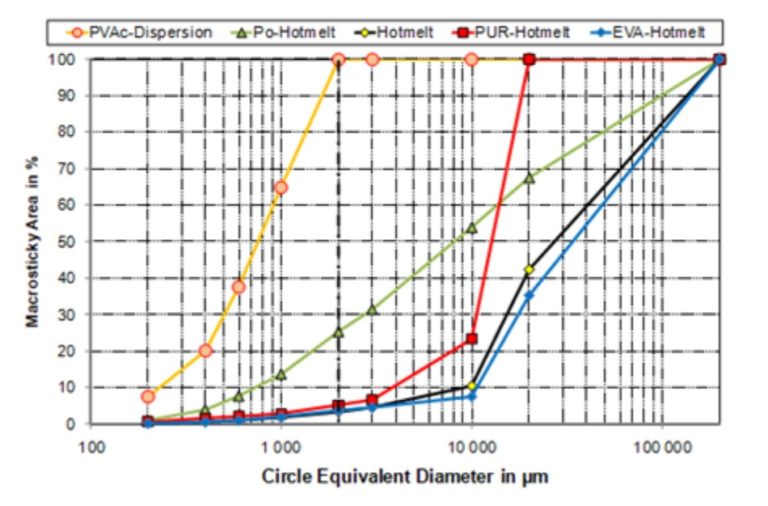

In a research project of INGEDE a variety of graphic paper products (catalogues, books, magazines) were investigated with their adhesive applications such as glued spines with side gluing (if relevant), the insert gluing of product samples or reply cards, and different kinds of PSA (pressure sensitive adhesives) labels. In this project, the fragmentation behaviour of the adhesive applications was studied on a laboratory scale and parameters developed to evaluate their impact in the industrial recycling process. A particle size of the macro stickies above 2 000 µm circle equivalent diameter as determined by means of INGEDE Method 4 is favourable in order to guarantee complete removal in a state-of-the-art recycling process.5 This particle size corresponds to the two dimensional sticky size after visualisation and is not equivalent to the three dimensional real particle shape in the pulp. Figure 1 shows some examples of macro stickies from different adhesive applications. It has to be seen that especially PSA paper labels create a large percentage of macro stickies below 2 000 µm diameter.

Figure 1. Average cumulative macrosticky area for different spine glue applications. 6

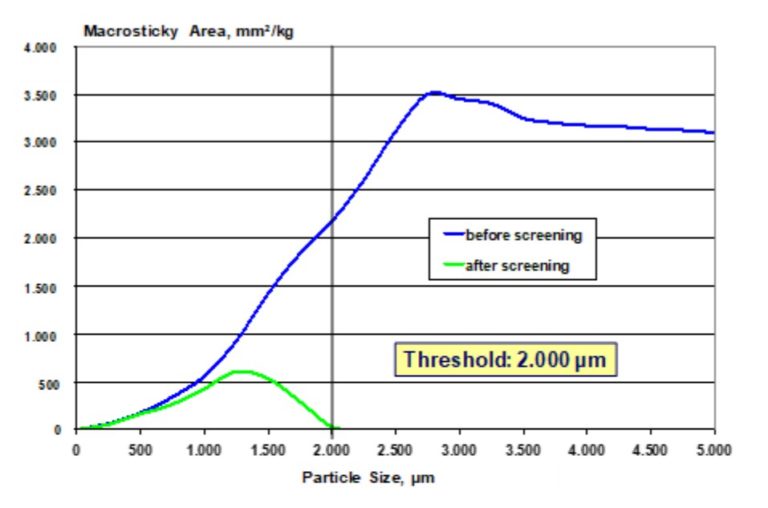

It has been verified on a pilot scale and in several mill-scale examinations that after screening in a modern industrial process no particles above the critical size limit xmin of 2 000 µm are existent in the recycled pulp (Figure 2). The efficiency in removing particles with a particle size below 2 000 µm circle equivalent diameter decreases with their size.

Figure 2. Macrosticky area distribution before and after industrial screening.

The two essential process steps in INGEDE Method 12 for graphic paper products are high consistency pulping with deinking chemicals in the same Hobart pulper as for the disintegration in the deinkability test. For adhesive applications from graphic paper products an alkaline high consistency pulping is defined together with woodfree copy paper with a defined ash content. It is assumed that the woodfree copy paper does not contribute to the measured macrosticky load from the adhesive application (Figure 3). Screening of the total defibred material follows stepwise under defined physical conditions in a Haindl or a Somerville classifier or a Pulmac MasterScreen.

Figure 3. INGEDE Method 12: Testing procedure of the fragmentation behaviour of adhesive applications.

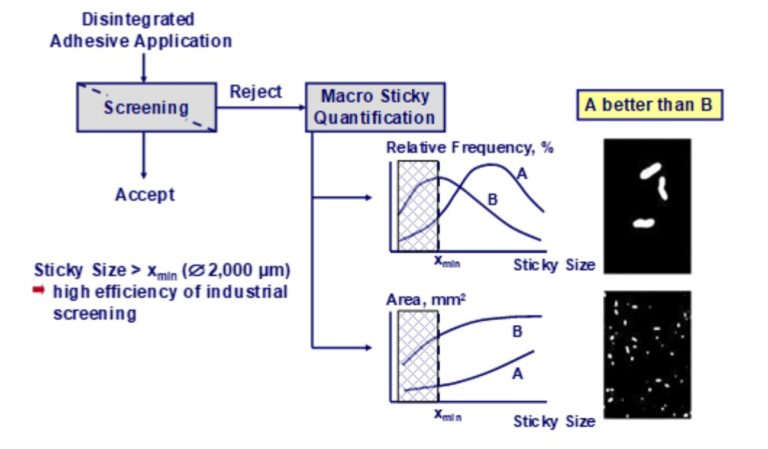

The particle size distribution of the macro stickies is measured (by area), thus allowing the assessment of the screening capability of the adhesives application in industry (Figure 4). Only the sticky particles below the critical size limit xmin of 2 000 µm circle equivalent diameter are of further interest. Particles above this size limit can be removed very sufficiently in industrial screening processes.

Figure 4. Assessment of sticky potential of adhesive applications in graphic papers according to INGEDE Method 12. 7

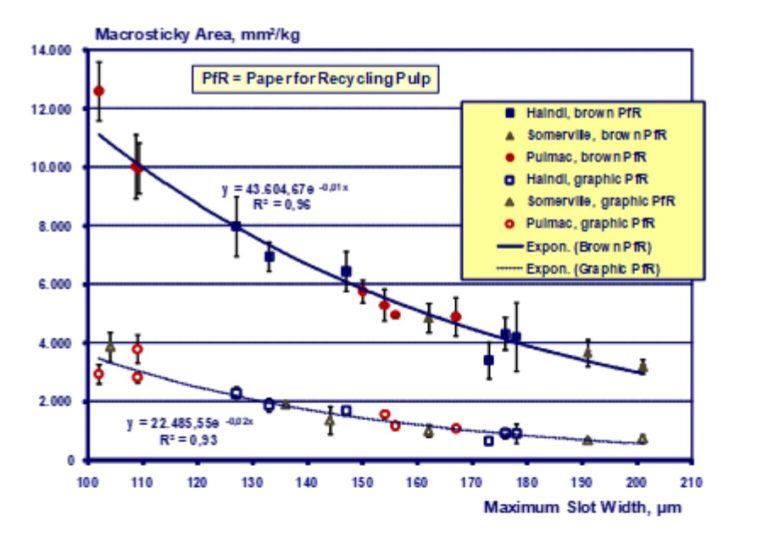

It is important to realise that the sticky result of a laboratory screening test depends not on the screening device used (Haindl classifier, Pulmac MasterScreen or Somerville classifier), but on the largest slot width of the applied screen plate. The nominal slot width is not sufficient for characterising a laboratory screen, because the width of the real slots always follows a frequency distribution and it is always the largest slot on the plate that finally affects the screening result (Figure 5).8 This is based on the fact that laboratory screening always takes a long time at high dilution which increases the probability that all particles smaller than the widest slot will pass the plate.

Figure 5. Correlation of macrosticky area versus maximum slot width (brown and graphic paper for recycling pulp).

Source https://forestbiofacts.com/

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project