Dry toner printing processes have their widest use in laser printers and copiers. There are different ways to create the latent image but without significant influence on deinkability. These electrophotographic processes commonly use powdered toners with a particle size of typically 5 µm to 10 microns.1,2 Most toners contain the general components listed in Table 1.3

Table 1. Toner components 3

| Component material | Function | |

|---|---|---|

| Colourant | Pigment or dye | Colour |

| Base binder resin | Blend of monomers: styrene acrylates, polyesters, epoxy-type resins | Fusing of toner particles |

| Modifier resin | Natural material: abietic acid, resin, wax | Enhance strength of toner/paper interface |

| Charge control agents | Quaternary ammonium salts, sulfonates, zinc complexes | Provide toner particle with electrostatic charge necessary for development |

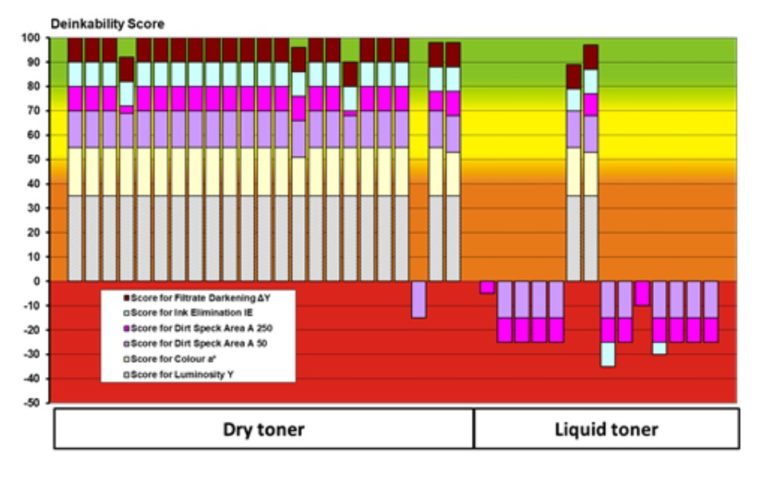

After printing, fixation and repulping, the dry toner particle sizes range from 25 µm to 250 µm.4 Their prints are usually well deinkable. The left part of Figure 1 shows that with one exception all other dry toner prints achieve the deinkability assessment “good”. The exception is a print with an unusual combination of toner and substrate.

High quality, high resolution print jobs sometimes use a liquid electrophotographic process. The technical advantage of this process is that the particle size of the toner is only about 1 µm.1 After printing, the toner films are very cohesive and flexible; they are not sufficiently during pulping. A significant proportion of the particles are above 500 µm. Therefore, because of the very high content of dirt particles in the deinked pulp, typically the samples of liquid toner prints fail to reach a positive deinkability score. There are so many toner particles left in the deinked pulp that in two cases even the ink elimination receives a negative assessment. But two liquid toner prints received a positive deinkability result. They belonged to a test series of 9 samples on different paper grades. The two papers with positive Deinkability Score were woodfree uncoated papers. The investigations will be continued.

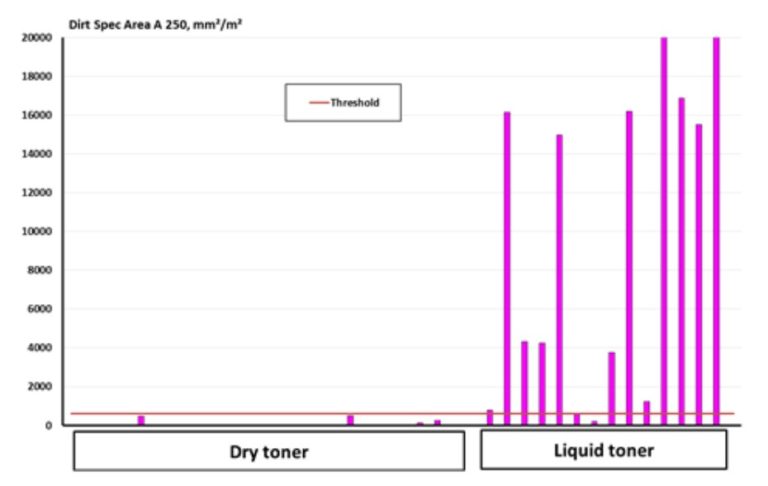

In the Deinkability Scores the negative scores are limited to the same absolute values as the positive scores. Therefore, the difference in dirt speck area between dry and liquid toner prints is not as prominent as implied by the raw data. Figure 2 shows the large, visible dirt specks above 250 µm particle size in deinked pulp from toner prints. Common dry toner prints have a dirt speck area in this size class between near zero until close to the threshold of 600 mm²/m² with an average of 72 mm²/m². Only one deinked pulp sample of liquid toner prints was below the threshold. Most of the samples were in a range between 15 000 and 20 000 mm²/m². For particles above 250 µm circle equivalent diameter in deinked pulp from liquid toner prints the average dirt particle area was 10.805 mm²/m², 18 times above the threshold.

Source https://forestbiofacts.com/

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project