Inkjet printers spray ink as tiny particles onto paper through electronically controlled fine jets. Inkjet inks need to have a low viscosity and contain a high proportion of vehicle, typically 60 % to 90 %. For printing on paper, water-based inks are most commonly used.1 There are different ways to create the image on the paper surface: thermal inkjet, piezoelectric inkjet and continuous inkjet. The deinkability is not dependent on the technology used to create the image but on the characteristics of the ink film, which in turn is determined by the ink components and the drying process. More than in other printing technologies, the characteristics of the substrate can have a positive influence on deinkability.

Inkjet inks are either dye-based or pigment-based. Dye-based inks contain only liquid components. The particles in pigment-based inkjet inks have a size below 0.15 µm.2 This can also be assumed to be the size of the particles after drying and repulping unless any agglomeration on the surface of the substrate takes place.

Drying normally is by absorption. An inkjet print on uncoated paper dries fast but often gives a low quality image due to low print density. This has triggered the development of paper surface preparations which provide sufficient drying time while keeping the ink at the surface, making use of agglomeration or precipitation. Another way is to use UV curing.

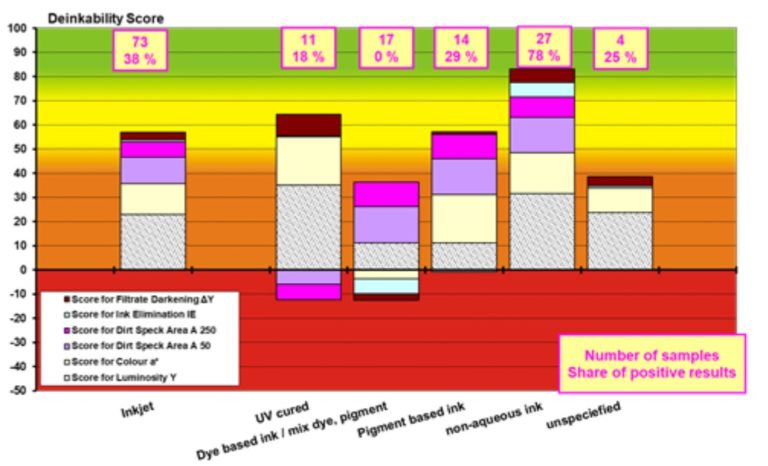

In total, from 73 tested commercial inkjet print products only 38 % obtain a positive Deinkability Score, as shown in Figure 1. Dye-based inkjet prints fail totally to achieve a positive deinkability result. From 17 deinkability tests no positive Deinkability Score was achieved. Discolouration of deinked pulp, too high filtrate darkening and too low ink elimination were the critical criteria for dye-based inkjet. Pigment-based ink jet prints behave better, but from 14 tests only 29 % got a positive Deinkability Score. From the UV cured inkjet prints only 18 % obtained a positive Deinkability Score. Similar to UV offset prints, the large dirt particle area of UV cured inkjet is the reason for failing deinkability. Some of the samples investigated according to the Deinkability Scores assessment scheme were inkjet printed newspapers which are nowadays promoted for small volumes and remote locations, e.g. foreign newspapers at international airports. Similar to flexographic prints, inkjet fail due to luminosity, ink elimination and filtrate darkening. In addition, the deinked pulps of dye-based inkjet prints show a pronounced greenish shade. Relatively good test results with more than three quarters were obtained with non-aqueous inks, also named solid inks on wax bases which become liquid by melting and then behave as a typical water-based inkjet ink. Beside another type of ink the printing technology requires a special heating unit to keep the ink liquid until it reaches the printing head.

The most promising way to improve the deinkability of inkjet is obviously the agglomeration or precipitation of pigment-based inks at the paper surface, but without significant commercial applications, actually.

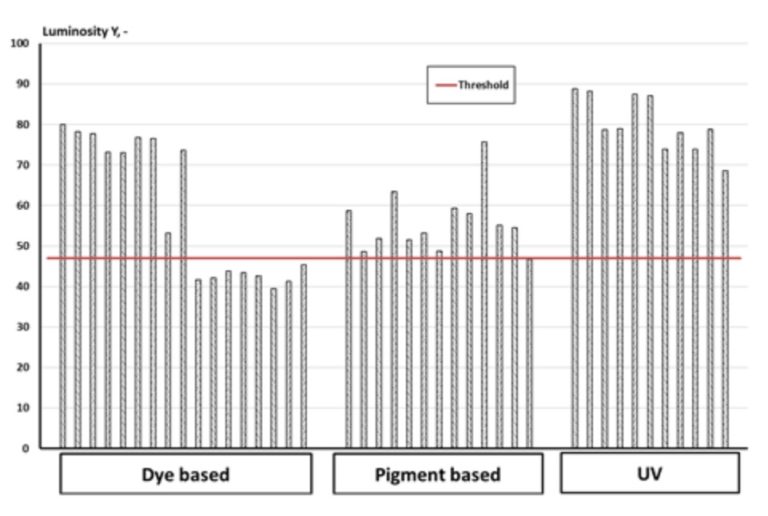

Dye-based inks contain chromophoric groups which can be colour-stripped by reductive bleaching agents in some cases.4 Bleaching is, however, not an essential part of the deinking process. Paper mills producing standard newsprint paper normally do not use a bleaching stage. Depending on the amount of dye-based ink on the paper, the luminosity of the deinked pulp exceeds the threshold or not, as can be seen in Figure 2. Typically pigment-based inkjet inks exceed the threshold and UV inkjet has, due to the cross-linked ink film, no problem with the luminosity of the deinked pulp.

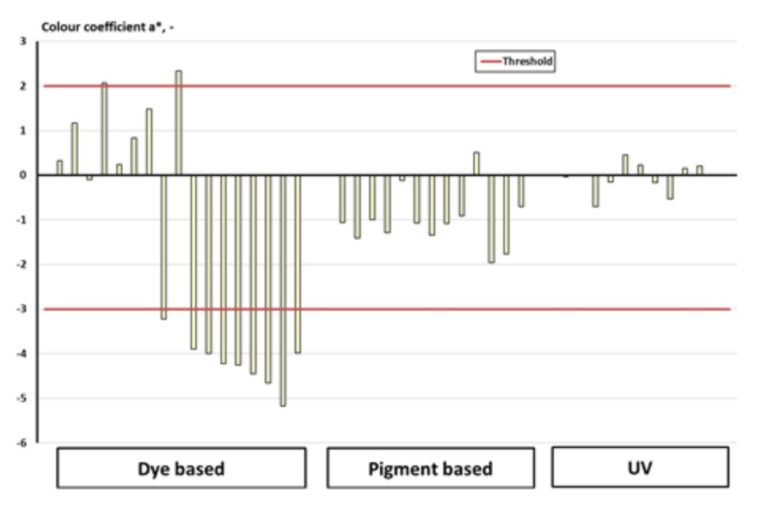

Pigment-based inks on standard paper do not differ much in their deinkability results from dye-based inks except the fact that they do not show a pronounced discolouration (Figure 3). The assessment is also “not suitable for deinking”. The situation can change with additional measures. The comparison of prints without and with bonding agent gives a hint at how an improvement can be made. The bonding agent is a chemical which is sprayed onto the paper surface as a primer and which agglomerates the ink at the surface. The motivation for this development was to improve the print quality on light weight standard papers; better deinkability is a windfall effect.

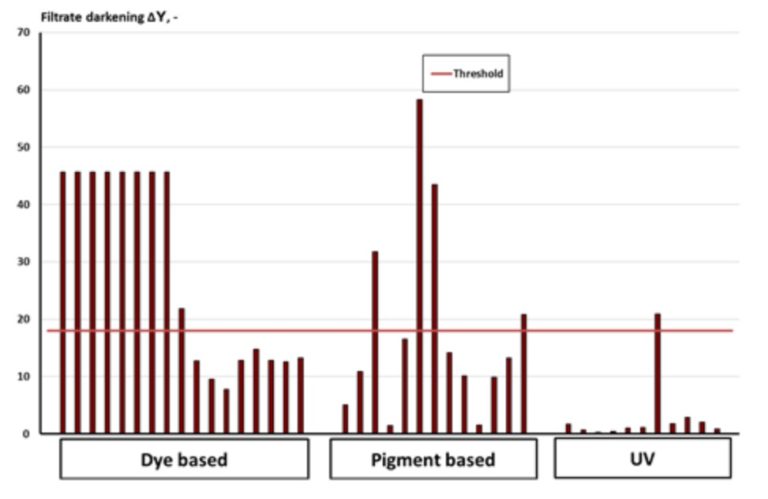

The deinkability test of the sample with UV-cured inkjet prints had also no problem with deinked pulp discolouration, but failed as well to achieve a positive assessment but for a completely different reason: the area of dirt specks was too high with values above the threshold for all particles larger than 50 µm as well as for the larger specks above 250 µm circle equivalent diameter. These results are in line with the tests of UV-cured offset prints. But one advantage of UV inkjet is that typically these print products have no problem with filtrate darkening, which is show in Figure 4. Only one sample exceeds the filtrate darkening threshold of 18. In contrast, dye- as well as pigment-based inkjet prints more often have problems keeping to the threshold limit.

Source https://forestbiofacts.com/

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project