Advantages

- Stable transportation, firm structure, lower power consumption

- Support rings set up for rollers to leave space between bale and roller surface so as to easily remove the bale wires

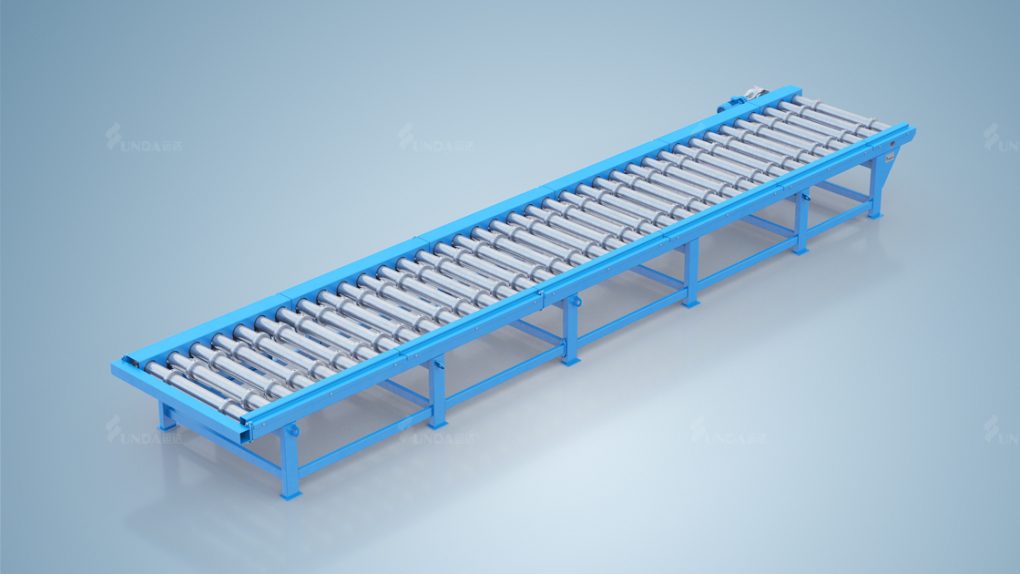

Structure and Principle:

The machine is composed of main drive carrier roller device, driven carrier roller device and machine frame, etc.

- Main drive carrier roller device

The device consists of motor, reducer, drive carrier rollers, chain wheel, mounted bearing and support ring, etc. The driving force is directly transmitted to the main shaft from motor through reducer, and then to the parallel driven carrier rollers through the chain wheel. The mounted bearing supports and fastens drive rollers on machine frame.

- Driven carrier roller device

Carrier roller device has driven carrier rollers, chain wheel, mounted bearing and support ring, etc. The mounted bearing supports and fastens drive rollers on machine frame.

- Machine frame

Made by welded channel steel, angle steel and reinforced plate.

Technical Parameter

| Model | KB1200 | ||

| Effective Conveying Width (mm) | 1200 | ||

| Conveying Speed (m/min) | 0-15 | ||

| Conveying Length (m) | L<8 | 8≤L≤14 | L>14 |

| Conveying Material | Pulp bale or pulp board | ||

| Motor Power | 1.5 | 2.2 | 2.2X2 |

Working site